Aluminum chemical etching individualISO 9001ISO 14001

Add to favorites

Compare this product

Characteristics

- Treated material

- aluminum

- Production method

- individual

- Certifications

- ISO 9001, ISO 14001

Description

In close collaboration with our customers, over the years we have developed innovative solutions for photo chemical etching of sheets and thus have pushed the limits of what is technologically possible.

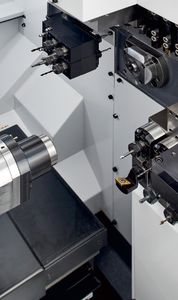

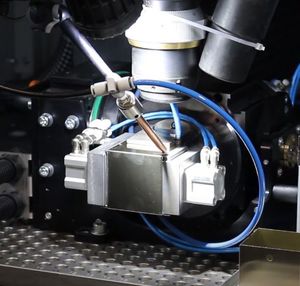

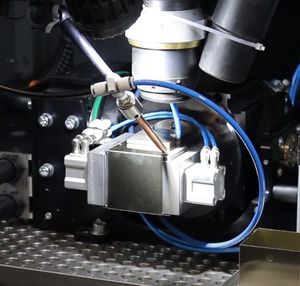

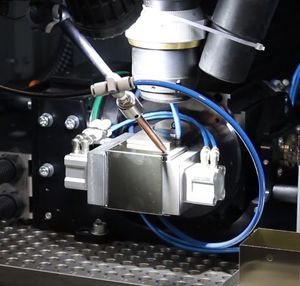

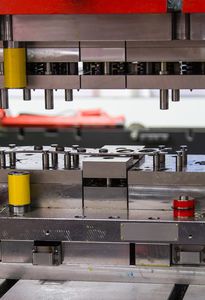

The photo chemical etching process makes it possible to manufacture photo etched parts in complicated geometrical shapes and tolerances which traditional mechanical plate working can not provide.

The precision metal plate etching technology is a cost-effective alternative to punching and laser cutting in materials that are up to 1.0 mm.

This photochemical machining technology can be used with a wide range of materials such as stainless steel, copper, nickel silver, brass and aluminium etching.

If you want to know more about our competences within precision metal etching, feel free to contact us.

Manufacture of complex geometrical shapes using many different raw materials

The products can also be delivered in strips, sheets or coiled and ready for automatic installation at the customer’s location

Chemical machining creates entirely tension and burr free components

There are typically no tool costs associated with the photochemical machining

Delivery can often take place within 2-3 weekdays

We can deliver prototypes within a few days as these do not require the use of fixed tools.

Upon delivery, the parts can be packaged as agreed with the customer and can also be delivered on:

Sheets

Strips

Rolls

It is also possible to deliver the parts ready for installation at the customer’s location.

The volume can vary from one individual piece to several million pieces.

Catalogs

No catalogs are available for this product.

See all of Mekoprint A/S‘s catalogsRelated Searches

- Anodic oxidation

- Aluminum anodic oxidation

- ISO 9001 anodic oxidation

- Passivation

- Powder coating

- ISO 9001 passivation

- ISO 9001 powder coating

- Steel powder coating

- ISO 14001 anodizing

- Chemical etching

- Metal chemical etching

- Aluminum powder coating

- ISO 14001 powder coating

- ISO 9001 chemical etching

- Prototyping chemical etching

- Aluminum passivation

- ISO 14001 passivation

- Stainless steel powder coating

- Individual chemical etching

- Aluminum chemical etching

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.