PVC plastic injection molding technical partsfor the electronics industryISO 9001

Add to favorites

Compare this product

Characteristics

- Material

- PVC

- Type of parts

- technical parts

- Applications

- for the electronics industry

- Certifications

- ISO 9001, ISO 14001

Description

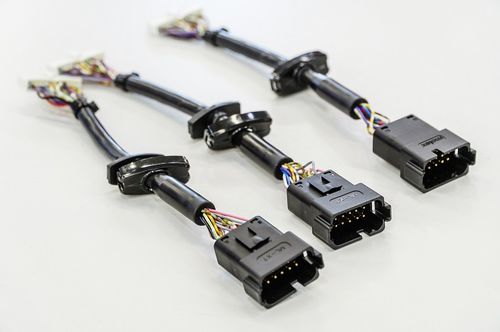

The purpose of molding cables and wires is to improve the service life and durability of cable solutions.

Mekoprint Cables offers low and high pressure die molding of cables for optimum protection, better tactility, easy installation and the option of branding, e.g. by embedding a customer logo.

Low pressure molding is a fast, gentle and environmentally friendly method used to protect electronics against mechanical impacts. The material is also electrically insulating and chemically neutral.

The tools used are manufactured in aluminium and have an attractive price level compared to conventional injection moulding tools.

The method is also used for molding in connectors to obtain an IP rating or a relief, molding in of branches or reliefs at panel ducts or the like.

MANUFACTURING WITH LOW PRESSURE MOLDING

Low pressure molding utilises the sustainable material Technomolt (formerly known as Macromelt).

Low pressure molding with Technomolt is an innovative alternative to injection moulding and potting that is both cost-effective and environmentally friendly.

Technomelt is a UL listed material approved in accordance with RoHS and REACH. The material is also made from 80% renewable raw materials.

Low pressure molding is excellent for protection of sensitive electronic components and connectors, welds and printed circuits.

The molding method has the advantage that it does not require high temperatures and pressure. Sensitive components are protected from these stresses.

Low pressure molding makes it possible to create unique cast plugs and connectors for specific tasks, where standard solutions do not provide a satisfactory result.

Catalogs

No catalogs are available for this product.

See all of Mekoprint A/S‘s catalogsRelated Searches

- Plastic injection molding

- Thermoplastic plastic injection molding

- Technical parts injection molding

- ISO 9001 cutting

- ISO 9001 plastic injection molding

- Laser cutting

- Prototyping cutting

- Individual cutting

- Injection molding for the electronics industry

- ISO 14001 plastic injection molding

- ABS plastic injection molding

- ISO 14001 cutting

- Plastic cutting

- Fine cutting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.