Aluminum passivation SURTEC 650ISO 9001ISO 14001

Add to favorites

Compare this product

Characteristics

- Type of substrate

- aluminum

- Certifications

- ISO 9001, ISO 14001

Description

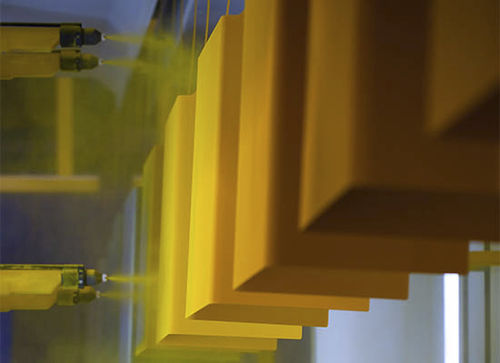

SURTEC 650 - SURFACE TREATMENT OF ALUMINIUM

Mekoprint is able to deliver customised solutions and so handle all stages of production. This means that we also deliver solutions in connection with the surface treatment of aluminium and other workpieces – including passivation with SurTec 650 as a surface treatment of aluminium.

SurTec 650 is a trivalent chromium compound for the surface treatment of aluminium, achieved through a dipping process. The treatment is electrically conductive and an excellent pretreatment prior to powder coating. The process complies with the corrosion requirements of MIL-DTL-81706-B and F-MIL5541. The colour is transparent to slightly blue/purple.

Amongst other things, the advantages of SurTec 650 are that the corrosion properties are improved, the surface’s electrical conductivity is retained and the aluminium’s binding capacity for, e.g. paints, adhesives and lacquers is increased.

FORMATS & MATERIALS

FORMATS

At Mekoprint, we have the following limitations regarding formats for the surface treatment of aluminium with SurTec 650:

The workpieces cannot exceed 2300 x 700 mm.

Contact Mekoprint if your workpieces exceed the above.

MATERIALS

We perform passivation with SurTec 650 of the following materials:

Various aluminium alloys, both from sheet and castings.

Contact Mekoprint to hear more about what materials we can handle in the process.

TECHNICAL INPUT AND OPTIMISATION

Mekoprint actively participates in every process – if needed. Therefore, we have many years of experience in providing technical advice and optimising everything from prototype to finished product.

Catalogs

Metal parts

4 Pages

Related Searches

- Anodic oxidation

- Aluminum anodic oxidation

- ISO 9001 anodic oxidation

- Passivation

- Powder coating

- ISO 9001 passivation

- ISO 9001 powder coating

- Steel powder coating

- ISO 14001 anodizing

- Chemical etching

- Metal chemical etching

- Aluminum powder coating

- ISO 14001 powder coating

- ISO 9001 chemical etching

- Prototyping chemical etching

- Aluminum passivation

- ISO 14001 passivation

- Stainless steel powder coating

- Individual chemical etching

- Aluminum chemical etching

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.