Flexible printed circuit FPC

Add to favorites

Compare this product

Characteristics

- Options

- flexible

Description

FPC AS AN ALTERNATIVE TO PCB

Etched, copper-plated foils are a highly cost effective alternative to conventional PCBs. In close cooperation with the customer, Mekoprint develops and manufactures single-sided, flexible printed circuits (also called flexprint or FPC).

The flexible circuit is produced on copper-plated foil rolls in combination with screen printing and etching technology. Due to the high conductivity of the copper, the foils are highly suitable as an alternative to traditional PCBs.

The foil-based circuits are flexible in structure (flexible printed circuits). This gives a special opportunity to apply them to curved surfaces, as well as printing continuous patterns across the length of the roll. This is particularly an advantage over the more rigid PCB panels.

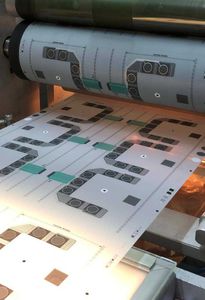

FULLY AUTOMATED PRODUCTION

The high degree of automation in Mekoprint’s roll-to-roll production setup creates cost-optimised solutions. The flexible circuit board is produced with minimal manual handling in all the processes – in printing, etching line and final finishing (laser cutting, die cutting, slitting, electrical testing and vision testing).

The special R2R-production setup of the flexible circuit on continuous foil rolls has significant advantages as regards cost, production time and quality.

FPC foils are delivered as single items stamped into format, on sheets or on rolls, prepared for fully automatic pick-and-place in the further processing in the customer’s production.

LED SUBSTRATE

With its high electrical conductivity, compared to, e.g. printed silver, flexible copper foils have proved particularly suitable for flexible LED panels.

Catalogs

No catalogs are available for this product.

See all of Mekoprint A/S‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.