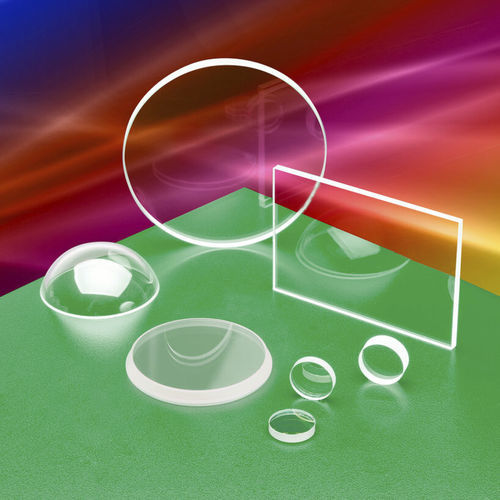

A full line of sapphire lenses, windows, and other shapes that feature highly precise tolerances for flatness, surface finish, and parallelism have been introduced by Meller Optics, Inc. of Providence, RI.

Meller Sapphire Substrates for Optical Coaters feature 1/10th per wave flatness per inch, surface finishes to 10-5 scratch-dig, and parallelism to 2 arc-sec, per MIL-PRF-13830, depending upon the configuration. Available in sizes from 1/2” to 5” O.D. with ±0.00025” tolerance, substrates can be supplied in unique shapes including pyramids with various modifications.

Featuring plano-convex and –concave, biconvex and –concave, and meniscus, Meller Sapphire Substrates can be plane, wedged, and tapered. Other substrate materials fabricated to specification can include silicon, zinc selenide, zinc sulfide, calcium fluoride, barium fluoride, magnesium fluoride, BK-7, quartz, and common laser glasses.

Meller Sapphire Substrates for Optical Coaters are priced according to configuration and quantity.