Preheater module PHM series

Add to favorites

Compare this product

Description

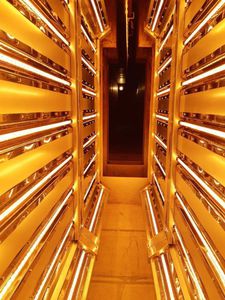

INFRERED PREHEATING MODULE

It is the pre-heating group consisting of the infrared heaters established in front of the painting curing and drying ovens in current conveyor type powder painting and liquid painting plants. The Pre- heating oven is positioned before the conventional oven air curtain.

The material is allowed to enter to the furnace in drying or curing temperature by ensuring the shorter pre-heating period for the product that will be dried or cured in conventional foven in order to maintain the temperature of the product heated by only infrared heater in the furnace an energy is consumed. By this means:

Current conveyor speed can be increased by 25% to 50%.

Conventional oven gas consumption is reduced.

In powder painting applications, because the paint enters into the conventional oven after gelling the quality problems caused by the paint flights are eliminated and the need for cleaning the oven is reduced.

Catalogs

No catalogs are available for this product.

See all of MEP TEKNIK‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.