- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

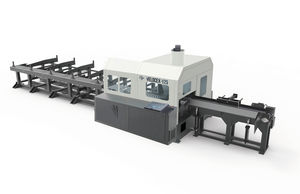

Circular sawing machine VELOCEX 100for steelfor profilesfor tubes

Add to favorites

Compare this product

Characteristics

- Technology

- circular

- Treated material

- for steel

- Applications

- for profiles, for tubes, for bars

- Operational mode

- automatic, CNC

- Other characteristics

- high-accuracy, with roller conveyor, single-blade, disc, for aviation, with cooling system, machining, PLC-controlled, high-speed, high-performance, carbide blade, with automatic feeder, single-head, programmable, variable-speed, with motorized head, servo-driven, with touch screen control, multipurpose

- Round piece diameter

Min.: 0 mm

(0 in)Max.: 100 mm

(4 in)

Description

MINIMUM USE OF RESOURCES TO MAXIMIZE PROFIT

highly efficient and productive high speed circular sawing machines

with tungsten carbide tipped or cermet blades, high productivity, good finish and

precise length and burr free cuts can be obtained on continuous basis!

0° cuts, suitable for ferrous & non-ferrous metals

solid - structural - section round / square / rectangular / hollow tubes

SOME FEATURES:

- “Set up wizard” for easy set up of jobs.

- For hollow sections special features such as slow entry, slow exit is provided.

- Diagnostics of all input, outputs and axis parameters.

- The blade feed motion is controlled by ball screw and servo motor.

- Chip auger for all type of materials with max discharge height of 400mm granting the right operational conditions of the saw.

- Hydraulic wire chip brush for constant removal of chips from the blade teeth granting a longer blade life.

- Automatic oil lubrication of most critical moving parts to grant the right operational conditions of the saw and consequently a longer life. Lubrication is timed through the main machine controller.

- Trim cuts and remnants are sorted automatically from good parts via heavy-duty discharge sorting chute

- Saw head slides on heavy duty Roller LMG bearings with ball screw.

- Variable cutting speed with frequency drive and rpm display.

- Electromagnetic powder break to eliminate gearbox backlash and enhance blade life.

- New bar entry in main vise made contact free by hydraulically lifting the bar in shuttle.

- The shuttle stroke is 1000 mm controlled by ball screw & servo motor.

Catalogs

VELOCEX 100

1 Pages

VELOCEX LINE

20 Pages

Related Searches

- MEP metal saw

- MEP automatic saw

- MEP circular saw

- MEP band saw

- MEP horizontal saw

- MEP cut-off saw

- MEP profile saw

- MEP precision saw

- MEP pipe saw

- MEP aluminum saw

- MEP miter saw

- MEP steel saw

- MEP semi-automatic saw

- MEP vertical saw

- MEP electric saw

- MEP saw with cooling system

- MEP hydraulic saw

- MEP compact saw

- MEP CNC saw

- MEP CE saw

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.