- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

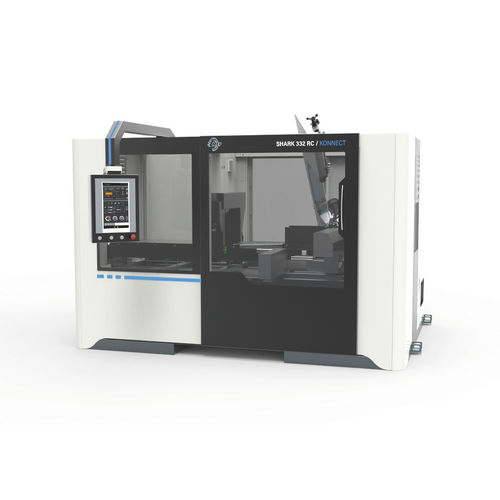

Band saw SHARK 332 RC KONNECTmiterfor metalsfor profiles

Add to favorites

Compare this product

Characteristics

- Technology

- band, miter

- Treated material

- for metals

- Applications

- for profiles, for pipe, for bars

- Operational mode

- semi-automatic, fully-automatic, CNC

- Other characteristics

- hydraulic, sliding, PLC-controlled, precision, with cooling system, carbide blade, with touch screen control, machining, electric, swivel, with automatic loading, single-blade, with roller conveyor, servo-driven, multipurpose, with chip conveyor, single-head, programmable, traveling-head, with automatic feeder, with motorized head, compact, CE, variable-speed, electro-hydraulic, inverter, with hydraulic vise

- Round piece diameter

130 mm, 160 mm, 200 mm, 250 mm, 310 mm

(5 in, 6 in, 8 in, 10 in, 12 in)

Description

The SHARK 332 RC KONNECT band sawing machine, fully automatic and with programmable double cutting angle, maximizes safety and power for reliable performance and intelligent production that is always efficient.

– Automatic hydraulic mitring band sawing machine, with double cutting angle between -60° and +60°, with automatic and semi-automatic cycle operation for cutting iron pipes, profiles and beams.

– “Operator-free” operation: with the self-positioning of the operating head and the vices, the automatic management of the scrap and the facing cut, the machine operation is fully automated, thus minimizing the operator’s programming and intervention times.

– Programmable automatic rotation of the operating head between -60° and +60° for symmetrical and asymmetrical cuts with brushless motor, which allows precise control in speed, torque and position.

– Cutting force control by means of an electric cylinder driven by brushless motor; the combination of the servomotor with ball-recirculating screw guarantees a precise control of the cutting dynamics with an immediate feedback response to all stress variations generated during chip removal.

– Double vice for optimal bar management: the movable vice automatically positions itself according to the programmed cutting angles, reducing the machine set-up times; the fixed vice contributes to better clamping while cutting and ensures that the position of the fed material is not lost during the feeder out-of-size.

– Rotating table mounted on a preloaded one-turn base fifth wheel to ensure a high number of automatic revolutions of the operating head.

VIDEO

Catalogs

SHARK 332 RC KONNECT

1 Pages

Related Searches

- MEP metal saw

- MEP automatic saw

- MEP circular saw

- MEP band saw

- MEP horizontal saw

- MEP cut-off saw

- MEP profile saw

- MEP precision saw

- MEP pipe saw

- MEP aluminum saw

- MEP miter saw

- MEP steel saw

- MEP semi-automatic saw

- MEP vertical saw

- MEP electric saw

- MEP saw with cooling system

- MEP hydraulic saw

- MEP compact saw

- MEP CNC saw

- MEP CE saw

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.