- Products

- Catalogs

- News & Trends

- Exhibitions

Laser profilometer railcontrolmobile

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Applications

- control, rail

- Configuration

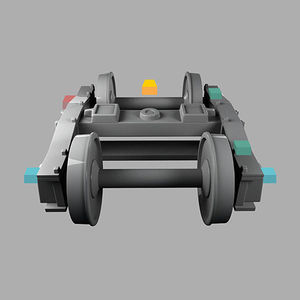

- mobile

- Other characteristics

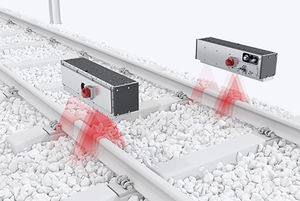

- non-contact

Description

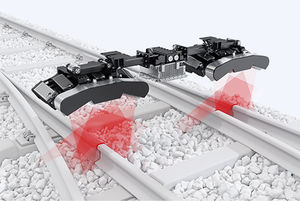

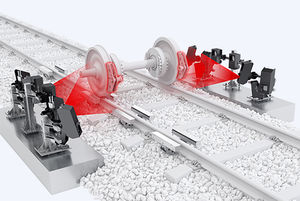

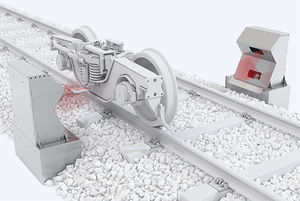

Ever-rising running speeds in railway lines require an intensification of rail profile control. Knowing the rail wear condition is crucial as it is strictly related to the key safety aspects of the railway infrastructure.

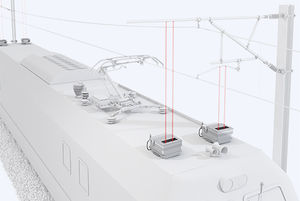

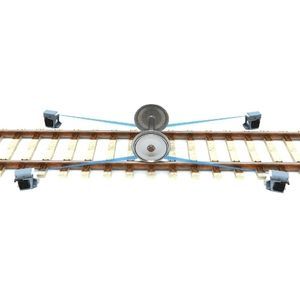

Along with the essential measurements like head width and crown radius, the wear at the top and the sides can be determined by comparison with the standard profile. It is also possible to measure the complete cross-section of a rail head and calculate the key data for both horizontal and vertical wear parameters.

Full Rail Profile

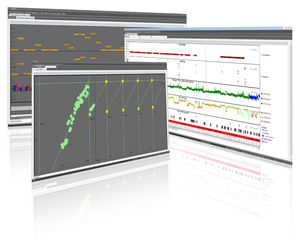

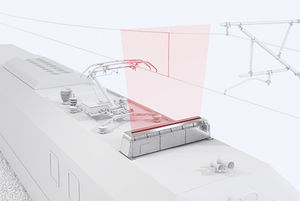

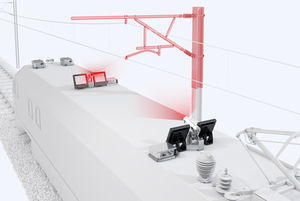

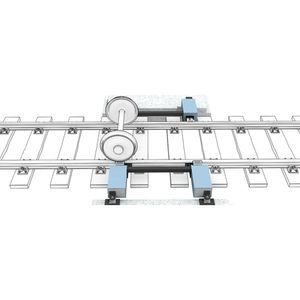

Integrated with Inertial or Chord Based Track Geometry, the Full Rail Profile features cutting-edge lasers and video camera technology provide accurate and immediate reporting on the profile and wear condition of the rail whilst traveling at track speeds. The cameras capture full cross-sectional rail profiles from the base/web fillet area up to the top-of-rail surface to allow comprehensive and accurate rail measurements and a functional integration with Track Geometry measured parameters.

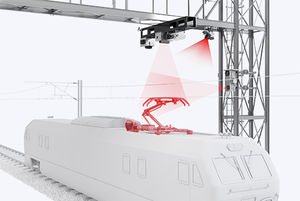

Full Rail Profile for Grinding

A specific aid to the grinding process. The high performance dedicated measurement system facilitates the maintenance and grinding operations to immediately compare rail grinding templates while traveling at track speeds. It is also possible to measure the worn area of the rail head and to automatically recognize the rail type. Grinding reports are available upon request.

Related Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Laser scanning system

- 3D scanning system

- Parts measuring machine

- Automatic measuring device

- Distance measuring machine

- Non-contact measuring machine

- Laser measurement system

- Diameter measuring machine

- Inspection scanning system

- Surface measuring machine

- Dimensional measuring machine

- 3D measuring machine

- Compact measuring machine

- Optical measuring device

- Rugged measuring machine

- Shape measuring machine

- Real-time measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.