- Products

- Catalogs

- News & Trends

- Exhibitions

Corrugation measurement system opticallaserfor rails

Add to favorites

Compare this product

Characteristics

- Measured physical value

- corrugation

- Technology

- optical, laser

- Measured material

- for rails

- Applications

- for railway applications

- Other characteristics

- compact

Description

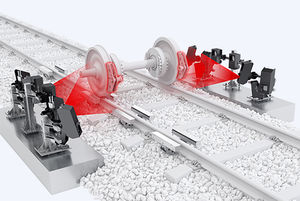

These defects can create a threatening vicious cycle by spreading defects on wheels and then onto the entire lower infrastructure. The increased dynamic interaction forces between wheel and rail caused by corrugation give rise to fastening, sleeper and ballast deterioration thereby reducing the life of track and vehicle components.

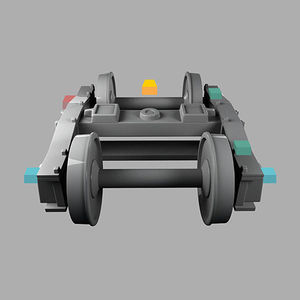

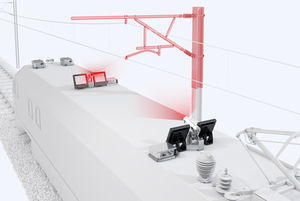

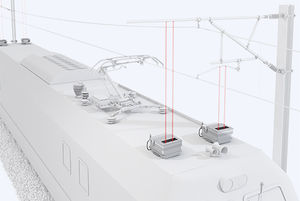

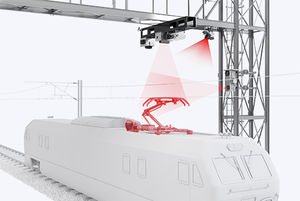

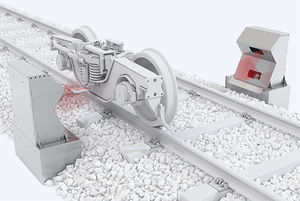

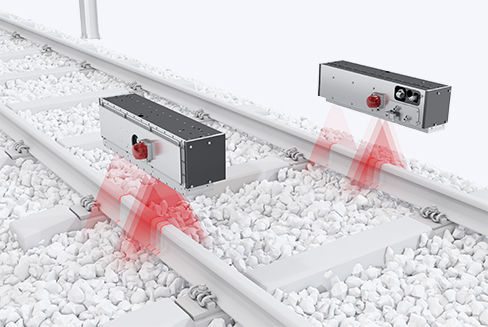

Highly accurate laser-based measurement system evaluating corrugation over four critical wavelength bands. Compact High Performance Laser Technology and High Precision camera sensors are able to accurately predict any longitudinal surface defect at any working speed.

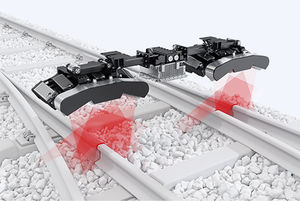

Chord-Based

MERMEC Rail Corrugation Systems (RCS) detect and measure rail corrugations ranging from short (10-30 mm) to long (1000-3000 mm) wavelengths. The system uses optical measurements of the rail surface profile by recording surface displacements with cameras and lasers through the Versine transfer function.

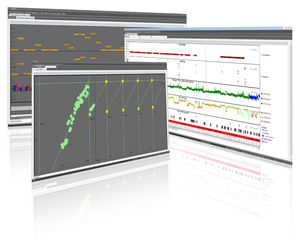

The measurement, with a sampling step up to 5mm and speed ranging from 0 to 160 km/h, can be done with the train travelling in both directions, in all weather environment and in any light condition. Each system offers real-time data analysis and post processing analysis including acquisition, storage and diagram visualization for all the wavelengths. The post-processing allows advanced calculations like the standard deviation for each wavelength. System can be configured to work in Grinding configuration in order to validate grinding works with few micrometer accuracy.

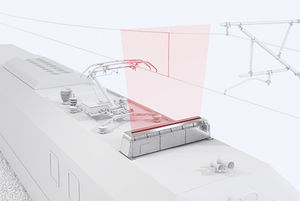

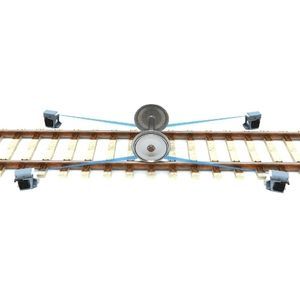

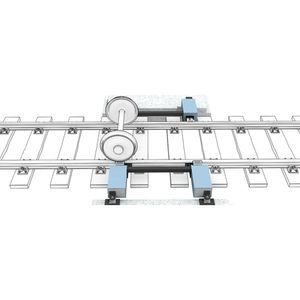

Inertial-Based

The system uses inertial-measurements of rail surface profile and inductively measured surface displacements to detect and quantify the condition of the rail surface.

Related Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Laser scanning system

- 3D scanning system

- Parts measuring machine

- Automatic measuring device

- Distance measuring machine

- Non-contact measuring machine

- Laser measurement system

- Diameter measuring machine

- Inspection scanning system

- Surface measuring machine

- Dimensional measuring machine

- 3D measuring machine

- Compact measuring machine

- Optical measuring device

- Rugged measuring machine

- Shape measuring machine

- Real-time measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.