- Products

- Catalogs

- News & Trends

- Exhibitions

Clearance measuring device T-Sight seriescameraopticallaser

Add to favorites

Compare this product

Characteristics

- Measured value

- clearance

- Technology

- camera, optical, laser

- Applications

- inspection, for railway applications

- Other characteristics

- automatic

Description

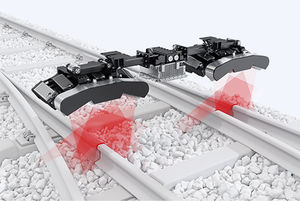

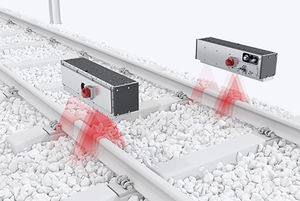

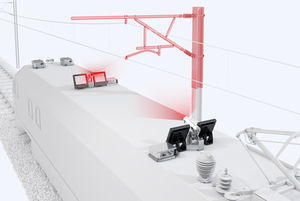

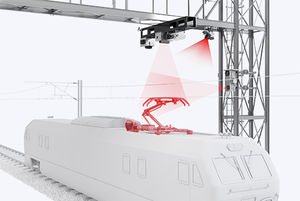

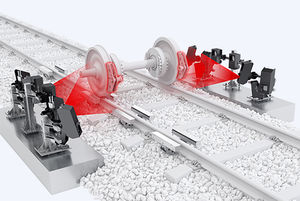

Clearance gauge measurement of railway lines is a decisive operation to ensure traffic safety. Huge damage may be caused even by small objects entering the allowed clearance area.

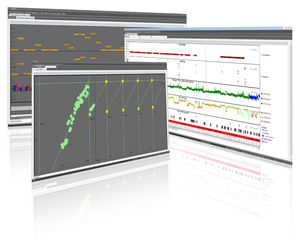

High performance Clearance Gauge and Tunnel Walls Inspection System combining "state-of-the-art" optoelectronics and machine vision technology for automatic surveying and real-time assessment of tunnels and infrastructure clearance. A mandatory in-depth inspection and analysis: tunnels and clearance profiles on railways, capturing image data of bridges, underpasses, poles, walls, tree branches, and other obstacles is the only way to ensure the safe transport of rail passengers and cargo.

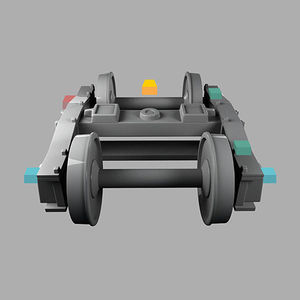

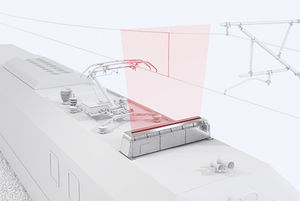

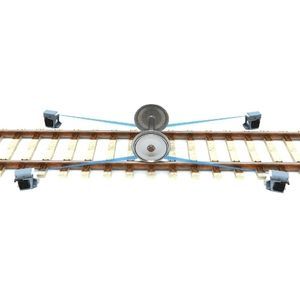

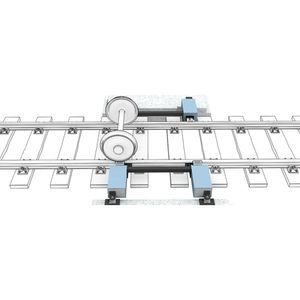

T-Sight 5000

The T-Sight 5000 uses High performances fixed cameras mounted in front of anamorphic mirrors custom-designed by MERMEC. These mirrors in combination with laser light reflected from the walls of the tunnel, allow a line profile from the complete 360° circumference of the FOV to be captured by the cameras at a maximum speed of 1000 gauge profiles per second. The detected gauge is compared with admitted profile and alarm reports with anomalies are computed automatically. Additionally, the system can host linescan cameras in order to get a complete 360° circumference image of the tunnel and surroundings. This images are processed by high performances PC and are used for tunnel wall inspection.

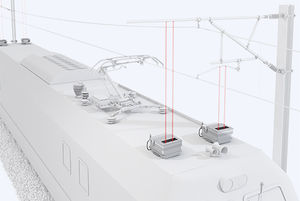

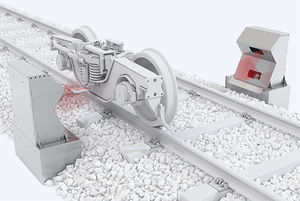

T-Sight 400

The system, using a rotating laser mirror, scans a 360° radius of the transversal profile of the railway line, so that violations with respect to the admitted profile are detected and alarm reports with the anomalies are sent to the maintenance staff.

Related Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Laser scanning system

- 3D scanning system

- Parts measuring machine

- Automatic measuring device

- Distance measuring machine

- Non-contact measuring machine

- Laser measurement system

- Diameter measuring machine

- Inspection scanning system

- Surface measuring machine

- Dimensional measuring machine

- 3D measuring machine

- Compact measuring machine

- Optical measuring device

- Rugged measuring machine

- Shape measuring machine

- Real-time measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.