- Products

- Catalogs

- News & Trends

- Exhibitions

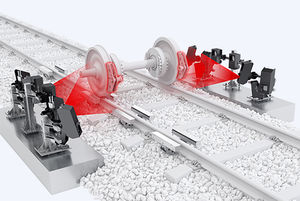

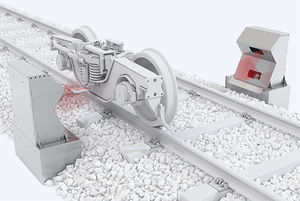

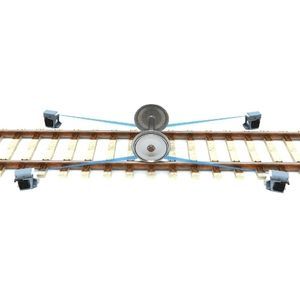

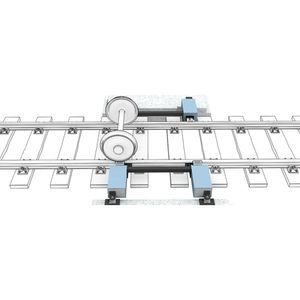

Laser inspection system Head Checkautomaticcrack detectionfor railway applications

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Operational mode

- automatic

- Type

- crack detection

- Applications

- for railway applications

Description

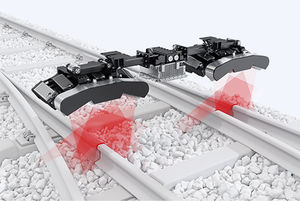

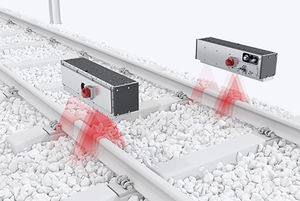

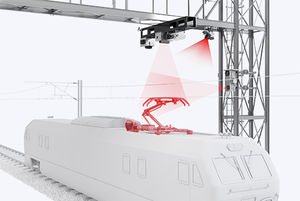

The new generation rail steels are of such high quality and are so resistant to abrasion that material wear is no longer sufficient to prevent the growth of cracks appearing in the rail surface such as "head checks" (defects occurring at the gauge corner of the rail).

This condition is a potential threat to rail integrity. Automatic and early-stage detection and precise localization of head checks when rail grinding is still a possible solution.

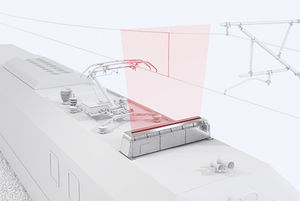

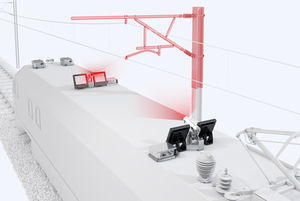

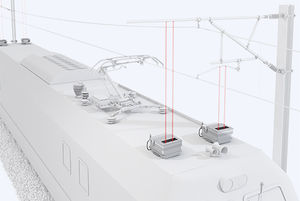

Head Check Detection

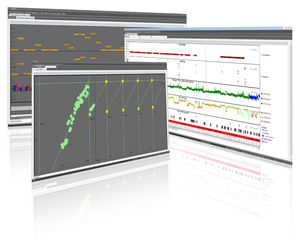

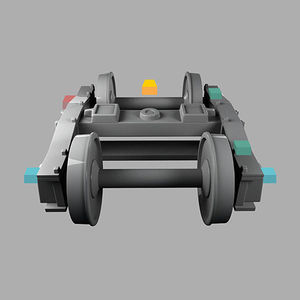

Head Checks Detection System is a high accuracy machine vision system able to identify head check defects in their early stage, when they can be removed by processing the surface of the rail, for example by re-grinding. System is able to identify sub-millimeter defects at an inspection speed up to 120 Km/h in any light and weather conditions.

Related Searches

- Inspection system

- Automated inspection system

- Camera inspection system

- Continuous monitoring device

- Tracker

- Measurement inspection system

- Surface inspection system

- Defect detection inspection system

- Management system

- Ultrasonic inspection system

- Surface defect inspection system

- Vehicle monitoring device

- Laser inspection system

- Load monitoring module

- Data tracker

- Multi-camera inspection system

- Cable inspection system

- Inspection system for railway applications

- Crack detection inspection system

- Force monitoring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.