- Products

- Catalogs

- News & Trends

- Exhibitions

Ultrasonic inspection system automaticfor defect detectionfor railway applications

Add to favorites

Compare this product

Characteristics

- Technology

- ultrasonic

- Operational mode

- automatic

- Type

- for defect detection

- Applications

- for railway applications

Description

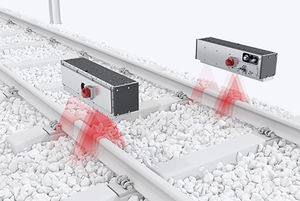

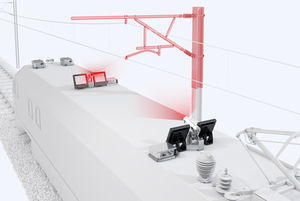

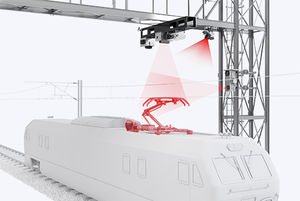

The ever-rising need to internally inspect the rail at high speed to avoid track possession and integrate it with high speed contact less technologies overcoming actual technologies limitations.

Vision systems can't simply do everything. Some of the most insidious defects develop within the rail. The full infrastructure assessment can be performed only including these internal flaws with the most advanced ultrasonic technology.

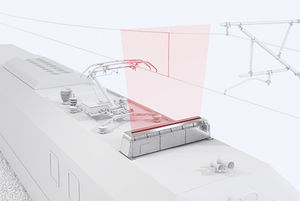

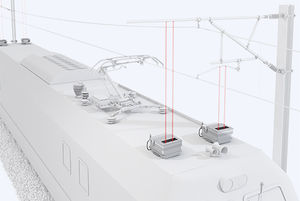

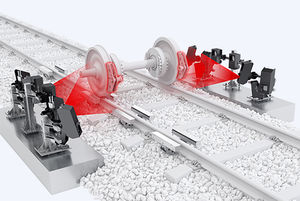

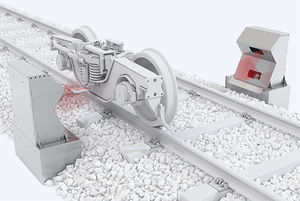

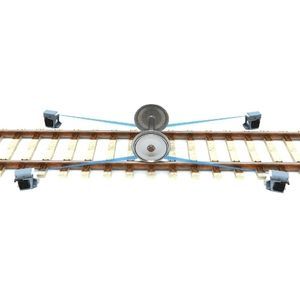

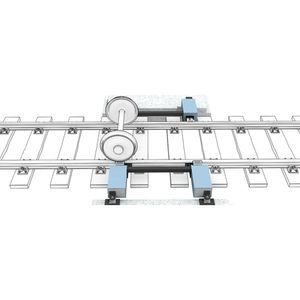

Ultrasonic Inspection

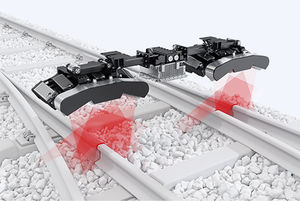

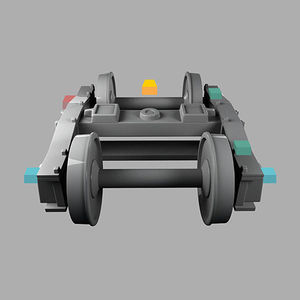

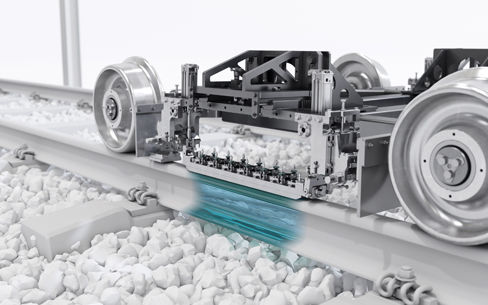

The Rail Flaw inspection system is based on a structure, which is connected to a dedicated boogie attached to the inspection vehicle. The mechanical interface holds all the transducer holders. This mechanical module is designed to keep the transducers in contact with the rail providing them with the required parameters to ensure proper coupling. The mechanical design is vital to keep such contact conditions while tracking the track route, so that the system will be able to inspect the track at speeds up to 100 Km/h (dependent on track surface and geometry conditions).

Related Searches

- Inspection system

- Automated inspection system

- Camera inspection system

- Continuous monitoring device

- Tracker

- Measurement inspection system

- Surface inspection system

- Defect detection inspection system

- Management system

- Ultrasonic inspection system

- Surface defect inspection system

- Vehicle monitoring device

- Laser inspection system

- Data tracker

- Load monitoring module

- Multi-camera inspection system

- Cable inspection system

- Inspection system for railway applications

- Crack detection inspection system

- Force monitoring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.