- Products

- Catalogs

- News & Trends

- Exhibitions

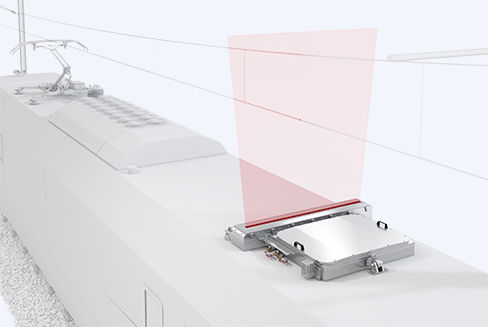

Laser measuring system for railsfor overhead cablesfor railway applications

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Measured material

- for rails, for overhead cables

- Applications

- for railway applications

- Other characteristics

- non-contact, high-resolution

Description

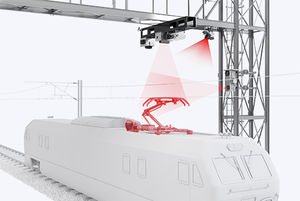

Ensuring the health of the catenary infrastructure is time consuming. A single catenary-related problem can block the entire network for hours.

Interactions with the pantograph that are either too hard or too soft, temperature changes during the year, wrong overhead line work execution and infrastructure failures can lead to an anomalous interaction between the pantograph and the contact wire contributing to further risks.

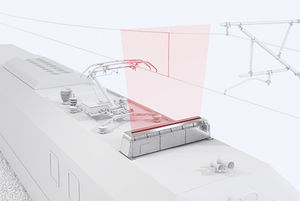

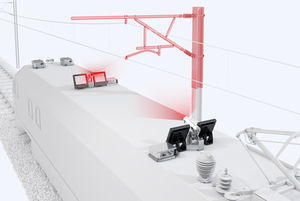

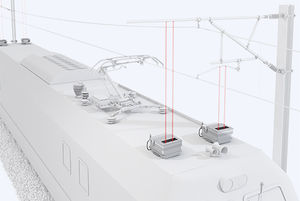

Geometry & Contact Wire Wear

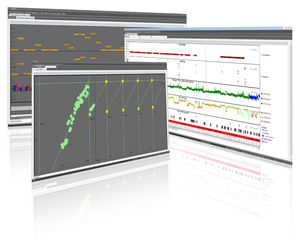

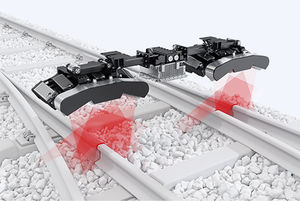

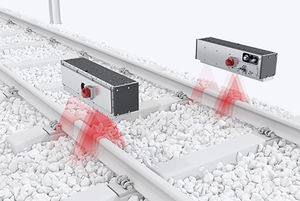

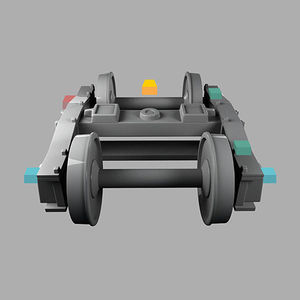

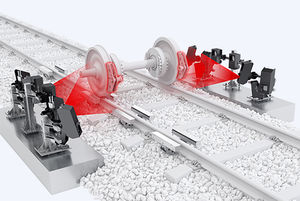

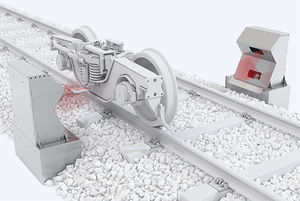

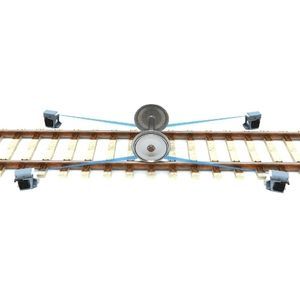

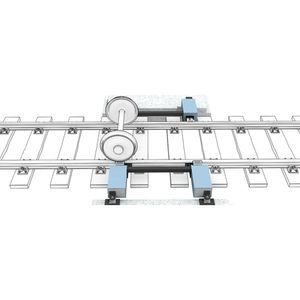

The Catenary Geometry & Wear System is a non-contact measuring system using laser scanners and high-resolution digital cameras to measure height, residual thickness and stagger of up to 8 wires simultaneously at a top speed of 320 km/h.

The cameras’ extremely small integration times eliminate blurring at very high speeds, making the MERMEC's measuring system the most accurate and high-performance on the market. With more than 5,000 measurements per second, the system helps maintenance staff to get the most life from the contact wires while increasing the safety of the line. Customizable sampling step ensures precise localization of any potentially dangerous weak spots caused by uneven wear or damage from electric arcs.

Related Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Laser scanning system

- 3D scanning system

- Parts measuring machine

- Automatic measuring device

- Distance measuring machine

- Non-contact measuring machine

- Diameter measuring machine

- Laser measurement system

- Inspection scanning system

- Surface measuring machine

- Dimensional measuring machine

- 3D measuring machine

- Compact measuring machine

- Optical measuring device

- Shape measuring machine

- Rugged measuring machine

- Real-time measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.