- Products

- Catalogs

- News & Trends

- Exhibitions

Camera inspection system automaticfor defect detectionfor railway applications

Add to favorites

Compare this product

Characteristics

- Technology

- camera

- Operational mode

- automatic

- Type

- for defect detection

- Applications

- for railway applications

- Product applications

- for power cables

Description

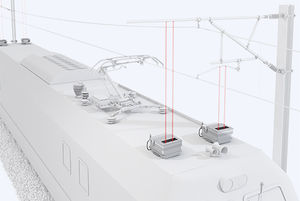

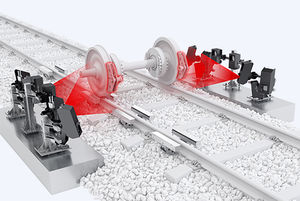

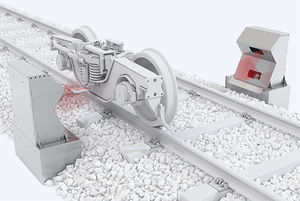

This specific inspection, together with the Longitudinal Defect Detection, is responsible for detecting Over Head Line components and their possible failures.

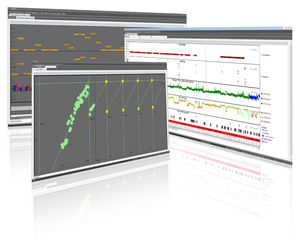

The processing algorithms need to recognize all the different elements of the overhead line with the related defects and automatically generate a list of faults.

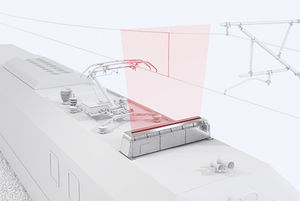

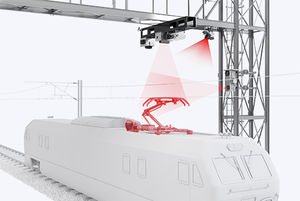

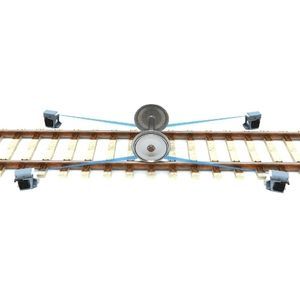

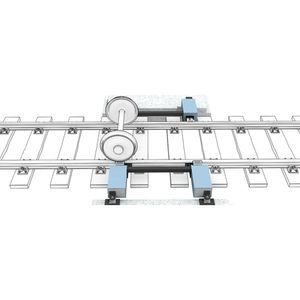

Transversal Defects Detection System

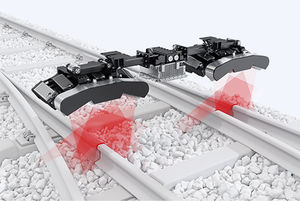

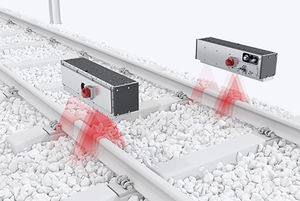

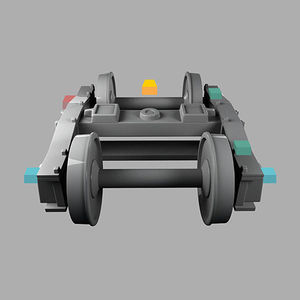

Based on high resolution digital cameras and high power illumination modules, the Transversal Defects Detection System acquires high resolution images of cantilevers, line hangers and insulators, residing in the transversal plane, and evaluates changes and/or corrosion in these objects. Through a double sided imaging process, triggered by the Pole Detection System, images are acquired on both sides of the cantilever infrastructure. Each defect is associated automatically to the kilometer/mile position on the track and the related image is saved in a file for further evaluation by the technicians.

Related Searches

- Inspection system

- Automated inspection system

- Camera inspection system

- Continuous monitoring device

- Tracker

- Measurement inspection system

- Surface inspection system

- Defect detection inspection system

- Management system

- Ultrasonic inspection system

- Surface defect inspection system

- Vehicle monitoring device

- Laser inspection system

- Data tracker

- Load monitoring module

- Multi-camera inspection system

- Cable inspection system

- Inspection system for railway applications

- Crack detection inspection system

- Force monitoring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.