- Products

- Catalogs

- News & Trends

- Exhibitions

Wear measurement system laserfor brake discsfor railway applications

Add to favorites

Compare this product

Characteristics

- Measured physical value

- wear

- Technology

- laser

- Measured material

- for brake discs

- Applications

- for railway applications

Description

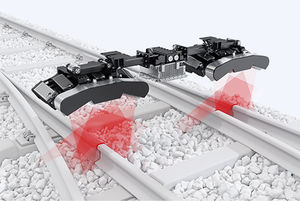

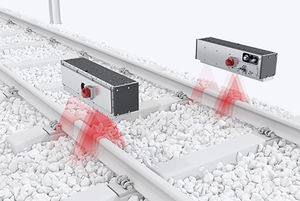

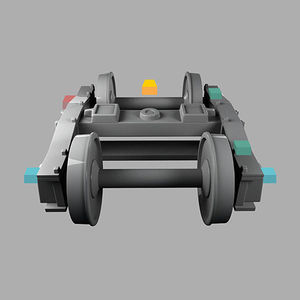

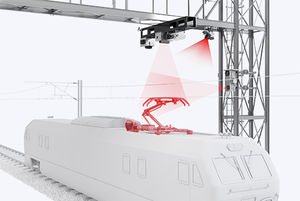

Brake are designed to wear out. Nevertheless the wear rate has to be monitored in order to maximize the brake life and prevent failures caused by an inefficient interaction with the wheels that can damage them.

Wear trends can then be established and used for predictive maintenance. The rail wheel, and in particular the brake and its interaction with the wheel, represent a decisive factor in the sphere of safety and quality of railway transport.

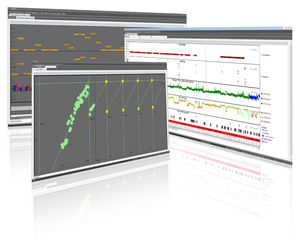

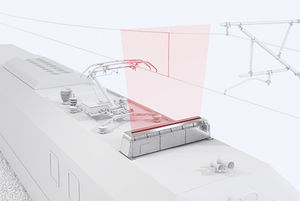

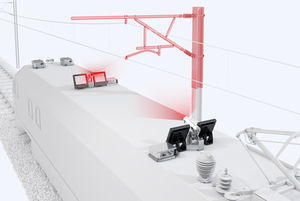

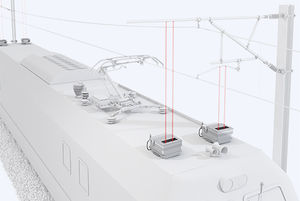

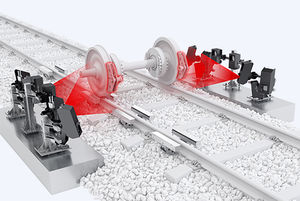

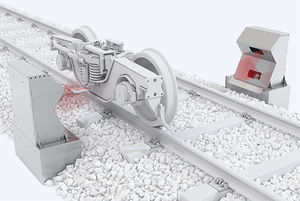

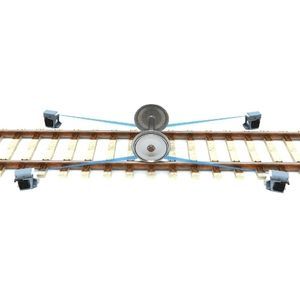

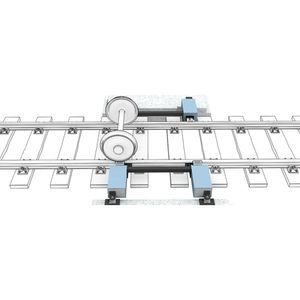

The complementary parameter to the brake wear is the brake disk wear which is monitored by a dedicated system. The measurement system acquires the brake disks profile by means of high speed laser-camera triangulation technology determining the actual wear status and distribution. The processing system performs the analysis of the measured parameters and comparison to defined tolerance thresholds. The analysis and reporting software provides performance trending and predictive identification of intervention dates.

Related Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Laser scanning system

- 3D scanning system

- Parts measuring machine

- Automatic measuring device

- Distance measuring machine

- Non-contact measuring machine

- Laser measurement system

- Diameter measuring machine

- Inspection scanning system

- Surface measuring machine

- Dimensional measuring machine

- 3D measuring machine

- Compact measuring machine

- Optical measuring device

- Rugged measuring machine

- Shape measuring machine

- Real-time measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.