- Products

- Catalogs

- News & Trends

- Exhibitions

Ultrasonic inspection system surface defectfor railway wheels

Add to favorites

Compare this product

Characteristics

- Technology

- ultrasonic

- Type

- surface defect

- Product applications

- for railway wheels

Description

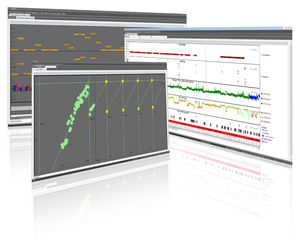

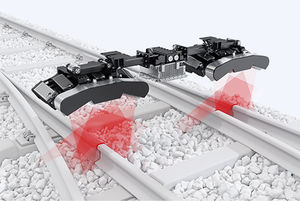

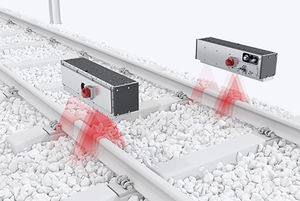

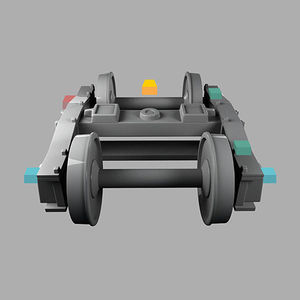

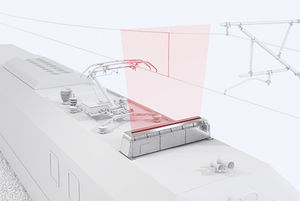

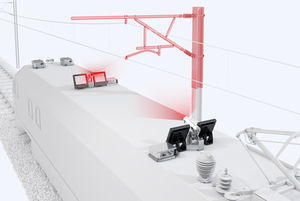

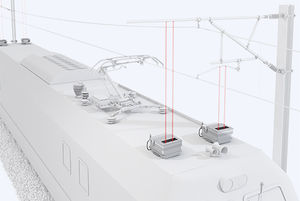

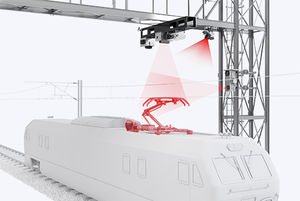

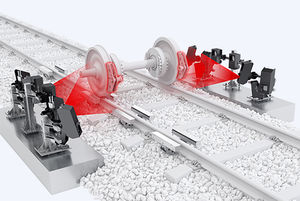

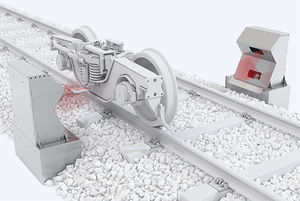

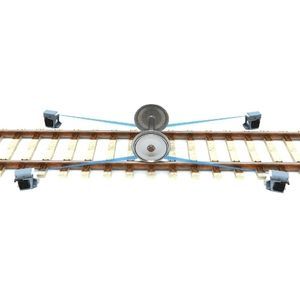

The wheel inspection systems using ultrasonic technology seeks out flaws and cracks by means of the propagation of Rayleigh ultrasonic waves produced electromagnetically on the rolling surface. The Rayleigh waves propagation through the surface defects determines the development of reflected waves that are automatically identified by the signal acquisition and processing software. The inspection system needs no coupling medium and its performance is independent of the surface conditions of the wheel, allowing proper operation even with rough or dirty surfaces.

Related Searches

- Inspection system

- Automated inspection system

- Camera inspection system

- Continuous monitoring device

- Tracker

- Measurement inspection system

- Surface inspection system

- Defect detection inspection system

- Management system

- Ultrasonic inspection system

- Surface defect inspection system

- Vehicle monitoring device

- Laser inspection system

- Load monitoring module

- Data tracker

- Multi-camera inspection system

- Cable inspection system

- Inspection system for railway applications

- Crack detection inspection system

- Force monitoring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.