- Production Machines

- Cutting Machine

- Fiber laser cutting machine

- MESSER CUTTING SYSTEMS

Fiber laser cutting machine ELEMENT Lfor metalsheet metalCNC

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal

- Product handled

- sheet metal

- Control type

- CNC

- Applications

- for industrial applications

- Other characteristics

- automatic

Description

Whether it is rapidly increasing laser powers, different fiber types or even new cutting gases: Today's laser machines must be able to follow current trends. Innovation is needed as applications must become more effective and transparent. In addition, the increasing shortage of skilled workers is pushing for plants to become more self-sufficient. One machine operator alone has to be able to supervise several machines.

Automation of nozzle change material supply and removal and continuous data exchange or reconciliation across the entire production flow are the prerequisites that were at the forefront of the ELEMENT L's development.

The new, easy-to-operate Global Connect CNC control equipped with 18.5” touchscreen helps to save paper and provides a clear overview of all production data in digital form

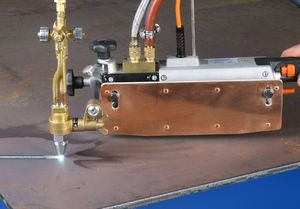

Selected premium components and smooth, vibration-free tool path movements thanks to helical rack and pinion drive systems

With modern fiber laser technology, a full enclosure that is light-tight under all circumstances is required.

In addition, its access points for material and people are monitored for safety.

Independent servo driven tools provide versatile processing options.

The ELEMENT is a flexible machine platform that can be specifically adapted to your application. As the ELEMENT L laser machine, it scores with remarkably high dynamics, the latest laser technology and the ability to economically process XXL sheets. Various features can be combined with powerful software to ensure maximum productivity and performance.

In this way, the ELEMENT L becomes a seamless total solution for metal processing in just a few steps

VIDEO

Catalogs

No catalogs are available for this product.

See all of MESSER CUTTING SYSTEMS‘s catalogsRelated Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Aluminum cutting system

- SS cutting machine

- High-performance cutting system

- Compact cutting system

- Steel cutting system

- Bridge cutting system

- Plasma cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.