Laser cutting extraction table

Add to favorites

Compare this product

Characteristics

- Applications

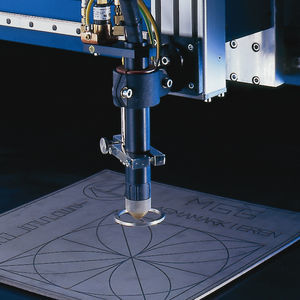

- for laser cutting

Description

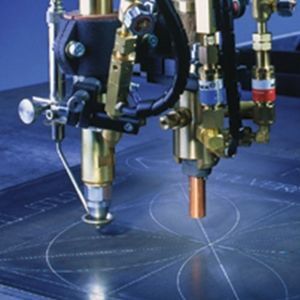

The fume extraction tables from Messer Cutting Systems ensure workpiece support for the cutting process and a very effective separation of the pollutants produced by thermal cutting.

The tables are a basic element for your cutting machine. The exhaust system is designed to load the material safely and extract pollutants in compliance with environmental regulations and environmental protection. The table is connected to the fan or filter unit. The filter ensures that, even the standards for clean air are satisfied.

The fume extraction table is divided into assembly and operating modules as well as into several exhaust sections. The exhaust sections are opened automatically depending on the burner location.

Gases and dust are captured at the optimum height of the table and taken through a system of openings and ducts into the filtration duct equipment.

• Modular construction of the tables for easy transport and installation

• Integrated mechanical or pneumatic control

• High load bearing and heat resistance

• Suitable for use with gantry and cantilever machines which are equipped with oxyfuel, plasma or laser cutting heads

• Single or multiple channel extraction with optimised requirements for the volume of air

Catalogs

No catalogs are available for this product.

See all of MESSER CUTTING SYSTEMS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.