- Packing - Handling - Logistics

- Packing and Packaging

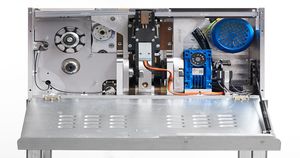

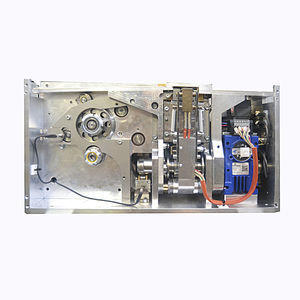

- Friction strapping head

- MESSERSI' PACKAGING

PP-PET strap strapping head MV300friction

Add to favorites

Compare this product

Characteristics

- Strap type

- for PP-PET straps

- Type

- friction

Description

The strapping head MV300 was patented by Messersì to provide maximum reliability and functionality ensuring limited wear of spare parts.

The welding by vibration is carried out for the fusion of the two surfaces in contact. The welding method is a clutch for which there is no heat input from outside but this comes from the dissipation of the energy produced by friction. The increase of local temperature required for the process is obtained by friction that melts the two pieces to be welded. In the cooling step the two pieces remain welded under pressure. On the piece subjected to movement, a pushing pressure is applied so as to maintain in contact the parts to be joined during the welding process.

Sealing of the strap: Friction system

Installed electrical power: 0,75 kW

Suitable strapping band: width 8 ÷ 19 mm thickness 0,5 ÷ 1 mm

Cycle time: from 1,2 to 3 sec (according to tensioning)

Tensioning: Up to 300 kg

Supplied voltage: 400 V three-phase 50Hz

Feeding and recovery speed: 2,5 ÷ 5,5 m/sec

Tensioning speed: From 0,10 m/sec to 0,25 m/sec

VIDEO

Catalogs

No catalogs are available for this product.

See all of MESSERSI' PACKAGING‘s catalogsRelated Searches

- MESSERSI' stretch wrapper

- MESSERSI' automatic stretch wrapper

- Stretch film wrapping machine

- MESSERSI' strapping machine

- Pallet wrapping machine

- MESSERSI' automatic strapping machine

- Shrink wrapper

- Automatic sleeve wrapping machine

- Turntable wrapping machine

- Strapping device and tensioner

- MESSERSI' packaging line

- MESSERSI' automatic packaging line

- MESSERSI' plastic strap strapping machine

- MESSERSI' vertical strapping machine

- Manual strap tensioner

- Rotary arm wrapping machine

- Rotary ring wrapping machine

- Semi-automatic strapping machine

- MESSERSI' 220V single phase strapping machine

- Heat-shrink film shrink wrapper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.