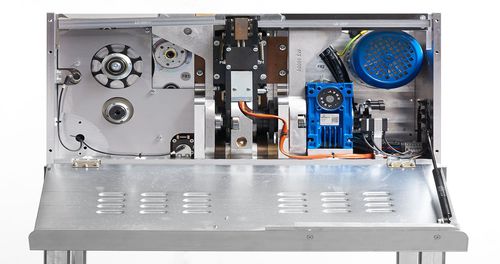

The patented strapping head MS300, has been assembled with high quality materials to guarantee low wearing of the spare parts.

It is the main functional element of any strapping machine, performing automatically all the feed and recovering, tightening, sealing and cutting operations. Extremely strong and compact, allows the machine to make automatically complete strapping cycle with one motor and one belt. The construction rationality and simplicity allow an easy and simple maintenance. The motor guarantees an uniform power and a low number of rotations assures low noise. It is controlled by inverter for energy saving.

In MS300 model , strap is sealed by thermo-welding system.

Strapping band sealing: Thermo-welding system

Installed electrical power: 0,85 kW

Suitable strapping band: width 8 ÷ 19 mm thickness 0,5 ÷ 1 mm

Sealing cycle time: from 1,2 to 3 sec (according to tensioning)

Strap tensioning: Up to 300 kg

Supplied voltage: 400 V three-phase 50Hz

Feeding speed: 2,5 ÷ 5,5 m/sec

Recovering speed: 2,5 ÷ 5,5 m/sec

Tensioning speed: From 0,10 m/sec to 0,25 m/sec

Total weight: About 100 kg