- Packing - Handling - Logistics

- Packing and Packaging

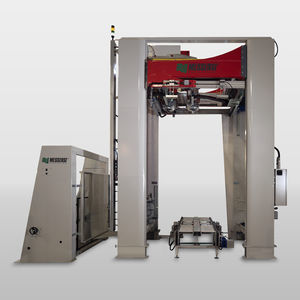

- Automatic hood machine

- MESSERSI' PACKAGING

Automatic hood machine SH51shrink filmvertical

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

- Type of film

- shrink film

- Other characteristics

- vertical

Description

The combined shrink hooding machine SH51 hoods and shrinks palletized products with tubular heat shrinking film.

The machine combines and synchronizes three different and independent phases: the preparation of the tubular film, transfer and opening of tubular film, hooding and heat shrinking- merging them together in a single process minimizing the downtime of various devices, providing exceptional levels of productivity (up to 140 packages per hour). The system for gripping and handling the tubular film is independent from the heat shrinking system: hence, the heat shrinking phase not interferes with the gripping phase, ensuring maximum reliability in terms of wear resistance of the components and wires. The lower extremity of the hood, driven internally by 4 grippers is tensioned and driven to the bottom of the package to assure a strong grip, simple and efficient, and to take advantage of the tubular film sizes, resulting in material savings. The burners have been designed to provide a constant heat and to guarantee a soft and uniform heat treatment of the hoods, enabling even the use of the thinnest films.

Moreover, the flame is lightened up only when the heat shrinking is required; therefore, it is more energy efficient than traditional ovens. Ergonomics is behind the project. The reel holder, considered standard up to 3 rolls , thanks to the positioning on a movable carriage , allows a fast, easy and safe access from the ground for reel loading. The combustion air distribution system inside the burner ensures optimum combustion without emission of unburnt gases in the environment.

VIDEO

Catalogs

Related Searches

- MESSERSI' stretch wrapper

- MESSERSI' automatic stretch wrapper

- Stretch film wrapping machine

- MESSERSI' strapping machine

- Pallet wrapping machine

- MESSERSI' automatic strapping machine

- Shrink wrapper

- Automatic sleeve wrapping machine

- Turntable wrapping machine

- Strapping device and tensioner

- MESSERSI' packaging line

- MESSERSI' automatic packaging line

- MESSERSI' plastic strap strapping machine

- MESSERSI' vertical strapping machine

- Manual strap tensioner

- Rotary arm wrapping machine

- Rotary ring wrapping machine

- Semi-automatic strapping machine

- MESSERSI' 220V single phase strapping machine

- Heat-shrink film shrink wrapper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.