- Products

- Catalogs

- News & Trends

- Exhibitions

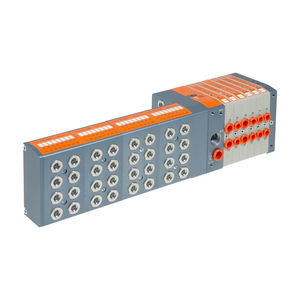

Spool pneumatic directional control valve SAFE AIR ® seriespneumatically-operatedelectrically-operated5/2-way

Add to favorites

Compare this product

Characteristics

- Type

- spool

- Actuating method

- pneumatically-operated, electrically-operated

- Ports/positions

- 5/2-way

- Other characteristics

- standard, for extreme conditions

- Operating pressure

Min.: 0 bar

(0 psi)Max.: 10 bar

(145.04 psi)- Flow rate

Min.: 700 l/min

(184.9 us gal/min)Max.: 4,600 l/min

(1,215.2 us gal/min)

Description

Starting from a series of sturdy, reliable valves, such as those to ISO 5599/1, some special features have been added, such as the presence of a valve status diagnostic system and the creation of a double channel guaranteeing architecture redundancy. The simplest version features one electropneumatically-operated 5/2 monostable valve. It is common knowledge that when this type of valve is in the idle state (coil not energized), port 1 is connected to port 2, and port 4 relieves. When the valve is operated (coil energized), port 1 is connected to port 4, and port 2 relieves. When the coil is de-energized again, the valve is returned to the idle state (so port 4 relieves) by means of a spring that returns the spool to the home position. In the event of a failure, the spool may remain in the actuating position, even with coil de-energized, leaving port 4 pressurized. To offset this problem, we have added a Hall-effect sensor that reads the spool position. This means that when the valve is deactivated, the sensor is on, and when the valve is activated, the sensor is off. A status in which the sensor is off and the coil de-energized indicates a problem.

This valve, which is available in 3 sizes for the ISO 5599/1 series, is a category 2 component according to ISO EN 13849 and is suitable for use in safety circuits up to PL=c

VIDEO

Catalogs

Related Searches

- METAL WORK valve

- Hand valve

- Control valve

- Stainless steel valve

- Ball valve

- METAL WORK pneumatic valve

- Threaded valve

- METAL WORK solenoid valve

- Regulating valve

- Stop valve

- Flap valve

- Non-return valve

- Electric valve

- METAL WORK gas solenoid valve

- METAL WORK directional control valve

- METAL WORK NC solenoid valve

- 2-way solenoid valve

- METAL WORK pneumatically-operated valve

- METAL WORK pressure regulator

- METAL WORK direct-operated solenoid valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.