- Products

- Catalogs

- News & Trends

- Exhibitions

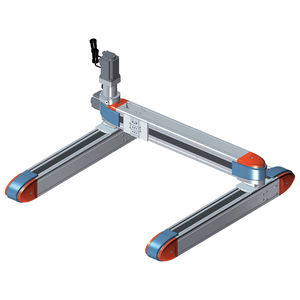

Low-friction cylinder STD seriespneumaticwith through roddouble-acting

Add to favorites

Compare this product

Characteristics

- Type

- pneumatic

- Technology

- with through rod

- Configuration

- double-acting, single-acting

- Norms

- ISO 15552

- Other characteristics

- low-friction, ATEX

- Stroke

Min.: 1 mm

(0.039 in)Max.: 2,800 mm

(110.236 in)- Bore

Min.: 32 mm

(1.26 in)Max.: 125 mm

(4.92 in)

Description

The low-friction cylinder is typically used as a dandy or tensioning cylinder since it is a single-acting cylinder without a return spring.

The configurations are shown below:

- The best type is A as it involves less friction.

- Type B should be used when the cylinder is working under normal conditions outside the pneumatic cushioning area.

Cushioning is only for emergency use. It acts as a shock absorber in the case of malfunction.

- Type C differs from type A due to the presence of a piston rod gasket that prevents dirt getting in when operating in dirty environments.

- Type D differs from type B due to the presence of a piston rod gasket that prevents dirt getting in when operating in dirty environments.

- Type E should be used when the pressurized chamber is the front one.

- For type F, see point 2.

Quantity per package: 0

Minimum order quantity: 0

Unit of measure: items

SEAL:

- FKM/FPM gaskets

- NBR gaskets

- Polyurethane gaskets

Catalogs

GENERAL CATALOGUE

1566 Pages

Related Searches

- METAL WORK cylinder

- METAL WORK actuator

- Linear actuator

- Electric actuator

- METAL WORK double-acting cylinder

- Hydraulic cylinder

- METAL WORK pneumatic cylinder

- Compact actuator

- METAL WORK single-acting cylinder

- Standard cylinder

- Industrial actuator

- METAL WORK compact cylinder

- METAL WORK rotary actuator

- Piston cylinder

- METAL WORK ISO cylinder

- METAL WORK aluminum cylinder

- Linear unit

- Precision actuator

- METAL WORK electric cylinder

- METAL WORK pneumatic actuator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.