- Food industry

- Meat Processing

- Vacuum meat tumbler

- Metalquimia S.A.

- Products

- Catalogs

- News & Trends

- Exhibitions

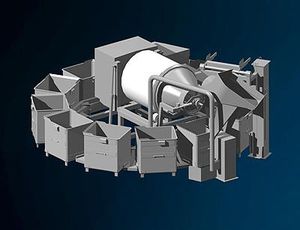

Vacuum meat tumbler Thermocomputer 3000Xwith cooling system

Add to favorites

Compare this product

Characteristics

- Other characteristics

- vacuum, with cooling system

Description

The THERMOCOMPUTER 3000X, a computer-controlled meat maceration system, is capable of fully automatic processing of different product types, without operator assistance, 24 hours a day, 7 days a week.

Automatic control of diverse parameters and its great operational versatility make it possible to obtain the highest quality and final yield in any type of meat product, regardless of the animal species or whether or not the pieces are processed whole.

•Capable of top performance of the latest technological developments in cooked meat processing.

•Facilitates diffusion and cellular absorption of injected brine, with ordered and precision-controlled maturation.

•Extracts myofibrillar proteins, homogenizing the meat pieces without destroying their morphology, and reduces cooking loss.

•Controls and registers meat maturation temperature.

System

•Programmable impacting and massaging maceration, from gentle to high-impact.

•Pulmonary action with alternating vacuum and overpressure cycles.

•Incorporated and simultaneous cooling.

•Exclusive system of drum tilt facilitates fast unloading, indispensable for obtaining a product with a high vacuum level (without foam or occluded air).

•Vacuum circuit without bottlenecks (from pump to drum) that ensures a high suction rate and maximum vacuum levels.

•Programmable maceration cycles for each product type with operative sequential programs of varying degrees of sophistication, in accordance with the customer’s requirements

•Variable drum rotation speed.

•Automatic on-line temperature control, with register of its real time evolution.

Related Searches

- Clipper

- Food clipper

- Steam cooking unit

- Vacuum stuffer

- Portioning machine

- Meat tumbler

- Sausage vacuum stuffer

- Vacuum meat tumbler

- Pneumatic clipper

- Automatic portioning machine

- Brine injector machine

- Meat industrial cooker

- Meat brine injector machine

- Batch industrial cooker

- Automatic industrial cooker

- Sack clipper

- Industrial meat tenderizer

- Meat tenderizer

- Meat portioning machine

- Meat tumbler with cooling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.