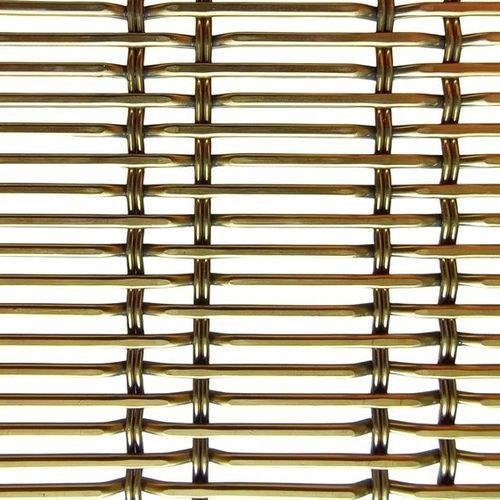

PVD Gold Architectural Mesh refers to a high-quality stainless steel mesh treated with a Physical Vapor Deposition (PVD) process to achieve a luxurious gold finish.

This suface treatment method involves the application of a thin, durable titanium-based coating, which enhances the surface of architectural wire mesh panels with a visually striking metallic sheen while maintaining the inherent strength and corrosion resistance of stainless steel, including the budgest interior grade SS201, most widely used SS304, as well as marine grade SS316 and SS316L.

The wire mesh is typically woven into long sheets or rolls and can be cut to the required sizes for various applications based on customer orders or specific project requirements.

Due to the size limitations of vacuum furnaces used in the PVD process, the mesh must be cut to appropriate sizes before the coating is applied.

The maximum size of the workpiece should be within 2m in width and a maximum length of 4.5m. The PVD process itself is conducted in a controlled vacuum chamber, where titanium particles are vaporized and then deposited onto the stainless steel surface, creating a strong, uniform coating that bonds at a molecular level.

Ideal for decorative and functional architectural applications, PVD gold-coated mesh adds a touch of elegance and sophistication to building facades, interior partitions, and various design elements, ensuring longevity and a consistent appearance over time.

The METART-WW26DB2-212 is a unique variant within the WW26 family, showcasing distinctive dual-sided decorative patterns.