- Production Machines

- Other Manufacturing Equipment

- Impact mill

- Metso Corporation

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Impact grinding mill OEDhorizontalfor powdershigh-capacity

Add to favorites

Compare this product

Characteristics

- Technology

- impact

- Orientation

- horizontal

- Product applications

- for powders

- Other characteristics

- high-capacity, large

Description

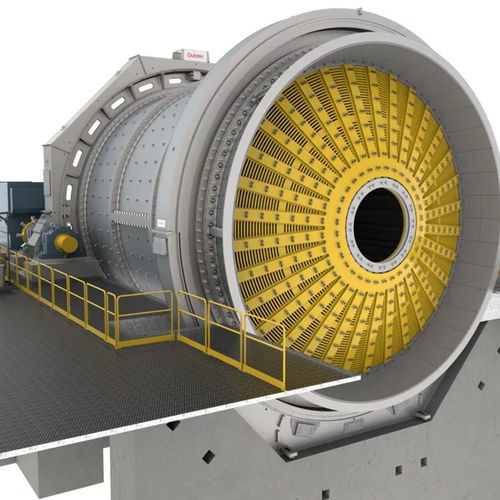

The Metso Outotec® Open Ended Discharge Grinding Mill (OED Mill) is a large grinding mill solution that enables innovative and efficient high capacity circuit designs through the removal of pulp lifters from the discharge arrangement. This facilitates significant reductions in both CAPEX and OPEX.

Highest possible discharge capacity through elimination of pulp lifters

Maximized slurry transport and impact energy with the lowest possible slurry pool level

Reduced CAPEX with novel high-capacity circuit designs

Minimized OPEX through the reduction or elimination of grinding media

Optimized serviceability and availability with novel discharge wear package

IMPROVE PROFITABILITY WITH INNOVATIVE HIGH-THROUGHPUT CIRCUIT DESIGNS

With decreasing ore grade quality and operating cost pressures driving the need to process higher tonnages and improve processing efficiencies, high-throughput circuits based on very large grinding mills are becoming an increasingly attractive option in mineral concentration applications.

HIGHEST POSSIBLE DISCHARGE CAPACITY

The OED Mill delivers the highest possible discharge capacity by eliminating the need for pulp lifters; instead, material is discharged directly through the grates, solving the throughput bottleneck problem often associated with comminution circuit design. The pursuit of high-efficiency pulp discharge systems by mill and liner suppliers is a testament to the potential upside of open-ended milling.

MAXIMIZED SLURRY TRANSPORT AND MINIMIZED SLURRY POOLING

The OED Mill has been designed to maximize slurry transport and minimize slurry pooling.

Catalogs

Related Searches

- Metso mill

- Screening unit

- Bulk material screening unit

- Horizontal grinding mill

- Vertical grinding mill

- Rotor lump breaker

- Vibrating sieving machine

- Impact grinding mill

- Waste lump breaker

- Roller grinding mill

- Building materials grinding mill

- Compact grinding mill

- Compact screening machine

- Mineral mill

- Mining screening unit

- Construction screening unit

- Dry milling grinding mill

- Powder grinding mill

- Rotary drum grinding mill

- Linear vibrating screening unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.