- Building - Construction

- Construction and Mining Equipment

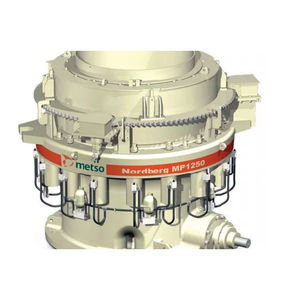

- Cone crusher

- Metso Corporation

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Cone crusher Nordberg® HP900™stationarysecondarycompact

Add to favorites

Compare this product

Characteristics

- Technology

- cone

- Mobility

- stationary

- Other characteristics

- secondary, compact, sand production, fine

- Capacity

Min.: 0 t/h

(0 lb/s)Max.: 2,000 t/h

(1,224.8 lb/s)- Motor power

700 kW

(951.73 hp)- Weight

77,960 kg

(171,872.38 lb)

Description

The Nordberg® HP Series has over 10,000 installations worldwide in a range of aggregate and mining applications. This equipment is well known as a market leader and continues to improve that point even further.

The Metso's Nordberg® HP900 comes with a new kinematic design and raised pivot points, but still shares about 80% of the same components are previous HP models. So we understand that this is new technology, but comes from a strong legacy in cone crushing so you can expect results.

Quick installation

The Nordberg® HP900 cone crusher is simple to integrate and install into any greenfield or brownfield plant. The drive system is pre-assembled and does not require any on-site construction. It also comes pre-wired with our integrated automation system, which minimizes adjustments and set-up usually needed before commissioning the crusher.

All HP900 cone crushers are factory tested before arriving on site, eliminating unnecessary downtime.

Cost efficient

Because of the HP900 cone crusher being pre-assembled, pre-wired and factory tested before arriving to the site, installation costs and time are reduced by 50%. The compact design provides a reduced plant footprint meaning your production will come from a smaller foundational requirement. Getting more from less.

VIDEO

Catalogs

Nordberg® HP900

2 Pages

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Metso mill

- Metso crusher

- Roller rail conveyor

- Metso stationary crusher

- Horizontal grinding mill

- Mobile crushing and screening plant

- Impact crushing and screening plant

- Materials handling conveyor

- Jaw crushing and screening plant

- Bulk products conveyor

- High-capacity crushing plant

- Metso primary crusher

- Metso secondary crusher

- Discharge conveyor

- Waste lump breaker

- Metso mineral material crusher

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.