- Production Machines

- Cutting Machine

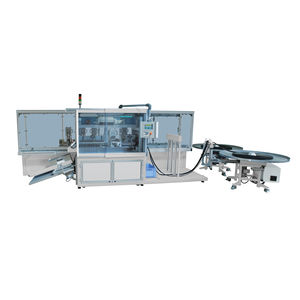

- Rotary blade cutting machine

- Metzner Maschinenbau GmbH

Rotary blade cutting machine TCMfor plasticsprofilePLC-controlled

Add to favorites

Compare this product

Characteristics

- Technology

- rotary blade

- Material

- for plastics

- Product handled

- profile

- Control type

- PLC-controlled, servo-driven

Description

Traveling-head machines for in-line processing of rigid profiles are often regarded as the »King Discipline« of cutting machine technology. Intensive dialogue with leading end-users and the many years’ experience of our designers have produced a ground-breaking product concept.

Thanks to a servo-linear drive as standard for the working tool carrier, the traveling-head machines achieve a very long processing time of several seconds for outstanding end-cut quality. At the same time, a very short cycle time is achieved for the processing of short part lengths at high line speeds. In addition, there is a servo-linear drive for the circular knife penetration with varying penetration speeds for different parts of the material section, for example a careful knife entry speed or a knife exit at lower speed to reduce the formation of sprags.

We also offer a great choice of knife rotation speed range alternatives, from 2,000 - 6,000 rpm or 4,000 -12,000 rpm. In this way, there are no limits to the use of different types of circular knife types, including clamp/cut in traveling head operation. For complete in-line processing of rigid plastic profiles, our traveling-head machines offer a powerful platform that can be adapted to many tasks by the employment of rapid-change tooling or drilling and milling modules.

Key Features

• For the “in-line” machining of rigid materials

• Precise and synchronous in-line machining for rigid materials

• Flexible retooling for different cutting technologies

• Holder for all tools in the Metzner MBS series

• Multiple machining with one workpiece carrier

• PLC controller as standard

• Optimised carriage return (as quickly as needed)

VIDEO

Catalogs

Other Metzner Maschinenbau GmbH products

Rubber and Plastics Processing - Profile Processing

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- Knife cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Cutting machine for the automotive industry

- High-performance cutting system

- Rotary blade cut-off machine

- Compact cutting system

- Steel cutting system

- Marking cutting system

- Profile cutting center

- Economical cutting system

- Textile cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.