- Machine-tools

- Machining Center

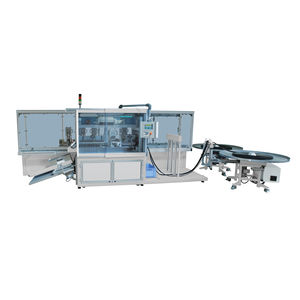

- CNC drilling machine

- Metzner Maschinenbau GmbH

CNC drilling machine verticalfor profileshigh-speed

Add to favorites

Compare this product

Characteristics

- Type

- CNC

- Structure

- vertical

- Applications

- for profiles

- Other characteristics

- high-speed

Description

Sealing systems often require ventilation drillings or location holes. For this purpose, Metzner drilling units are employed. We deliver the following solutions to match your requirements:

In-line eccentric-drive drilling station for regular drillings at constant pitch

In-line traveling-head drilling station for constant or variable pitch drillings

In-line »Drilling Beam« to drill all the holes for a complete profile at different pitches in one action

Off-line for drilling in combination with end cutting

Metzner drilling units are distinguished by drill spindles with very high speeds up to 60,000 rpm. This gives precision drillings with short cycle times. The drill geometry ensures that the waste generally falls to the outside. Pneumatically driven drilling spindles have the advantage of lower investment cost but have higher running costs. Electrically driven drilling spindles cost less to run but are a more expensive investment.

In addition, Metzner supply laser drilling systems for in-line operation. Lasers are more expensive but offer the advantage of processing variable hole pitches during automatic running and can be employed in changeover to different profiles.

Key Features

• For continuous drilling in extrusion operation

• Automatic synchronisation with line speed

• Selectable, program-controlled drill spacing

• Maximum precision due to simultaneous drilling and cutting

VIDEO

Catalogs

No catalogs are available for this product.

See all of Metzner Maschinenbau GmbH‘s catalogsOther Metzner Maschinenbau GmbH products

Rubber and Plastics Processing - Profile Processing

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.