- Machine-tools

- Machining Center

- Linear transfer machine

- Metzner Maschinenbau GmbH

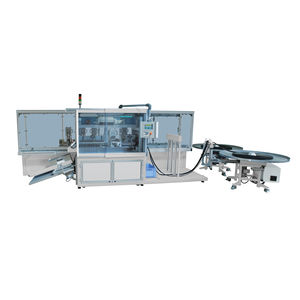

Linear transfer machine CNC12-positionhigh-accuracy

Add to favorites

Compare this product

Characteristics

- Type

- linear

- Control type

- CNC

- Number of positions

- 12-position

- Other characteristics

- high-accuracy, programmable, automatic, precision

Description

The basic idea: Highest productivity combined with highest precision is the outstanding characteristic offered by automatic Metzner Transfer Type Machines.

Metzner develops and builds automatic transfer type machines for the complex finishing of automotive seals for example at the Glass Run Channel or the Door Weather Strip. In the process, mounted within a special clamping, the profile is transported automatically to individual cutting stations by a transfer system. Phase-controlled by a programmable system, the particular cutting is then performed at the tooling station. After all individual steps are completed, the processed part is dispensed.

The processing within a fixed clamping combined with the precision of a servo-system and additional positioning sensors guarantees the compliance with continuously tighter manufacturing tolerances and high repetition precision.

Metzner transfer type machines offer an especially high cost-effectiveness for vehicles produced between 50.000 and 250.00 units per year.

Automatic component feeding and component take-off with a robot or other handling systems put unmanned manufacturing within reach.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Metzner Maschinenbau GmbH‘s catalogsOther Metzner Maschinenbau GmbH products

Rubber and Plastics Processing - Profile Processing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.