- Production Machines

- Cutting Machine

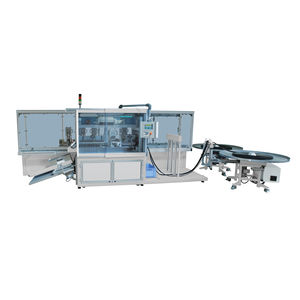

- Rotary blade cutting machine

- Metzner Maschinenbau GmbH

Rotary blade cutting machine CCM Series for metalfor plasticsfor rubber

Add to favorites

Compare this product

Characteristics

- Technology

- rotary blade

- Material

- for metal, for plastics, for rubber

- Product handled

- profile, tube

- Control type

- PLC-controlled

- Applications

- for extrusion lines

- Other characteristics

- programmable, with automatic feeder

- Cutting speed

30,000 mm/min

(19.685 in/s)

Description

Circular knife cutting machines of the »Metzner CCM series« have been developed to ensure reliable processing of flexible, steel-reinforced and rigid materials.

The rotating circular knife is perfectly suited to cutting rubber, plastic and metal and gives extremely good cutting quality by the combination with other parameters such as optimum material guide, knife rotation speed, knife rotation direction, knife feed and knife lubrication, ensuring both, »in-line« and »off-line«.

Central to all »CCM machines« is that they are fitted with a linear servo-drive for the circular knife arm movement. This feature allows various feed speeds for working on different materials, e.g. inserting material gently for the best possible cutting result or a slow feed for removing the blade to reduce the formation of sprags and burrs. All circular knife cutting machines of the »CCM series« can be supplied with a knife speed range from 1.000 – 6.000 rpm or 4.000 – 10.000 rpm. This means that, as well as circular knives, abrasive discs can also be used in combination with a profile clamping system to optimize the end cut surface quality by a grinding action.

The PLC control can be programmed freely, allowing for all the processing parameters to be set to meet the demands of various profile contours and mixtures of materials. These parameters can be saved and then used again at the press of a button.

VIDEO

Other Metzner Maschinenbau GmbH products

Rubber and Plastics Processing - Profile Processing

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- Knife cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Cutting machine for the automotive industry

- High-performance cutting system

- Compact cutting system

- Rotary blade cut-off machine

- Steel cutting system

- Marking cutting system

- Profile cutting center

- Economical cutting system

- Textile cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.