- Production Machines

- Cutting Machine

- Rubber cutting machine

- Metzner Maschinenbau GmbH

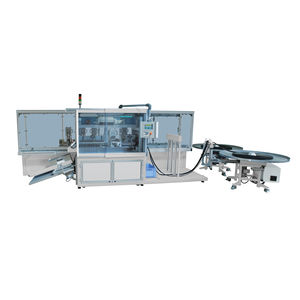

Profile cutting machine MBS Seriesfor plasticsfor rubberPLC-controlled

Add to favorites

Compare this product

Characteristics

- Material

- for plastics, for rubber

- Product handled

- profile

- Control type

- PLC-controlled

- Other characteristics

- modular

Description

Metzner cutting machines of the »MBS series« represents outstanding flexibility in the processing of flexible and semi-rigid profiles of rubber and plastic. Different cutting processes and machine components provide cutting machines that fit flexibly and individually with customers’ requirements and are available in the shortest time with practically no development being necessary.

Many processing and cutting tasks are as varied as the materials themselves. With the MBS-System it is possible for you to combine more than 130 standard components together to fit your requirements. Just like building blocks, the appropriate elements are selected and applied. Elements like the type and number of cutting tools, length of the transport conveyor (from 200mm up to 800mm) and width (from 100mm up to 400mm), control system, feed-in device, working direction, nature of the transport conveyor surface covering and the support framework: all these are tailored to the needs and demands of the customer and the materials. Thanks to this flexibility, there are virtually no limits to meeting and satisfying your requirements.

The use of standard components makes it possible to create the MBS machines very quickly with very little further development. Modular cutting machines are thus not only matched to processing requirements but are also extremely economical and efficient. In addition, all MBS machines are equipped as standard to be fully integrated with peripheral systems such as take-off and feed mechanisms, throw-off devices and winders, printers and marking units.

VIDEO

Catalogs

Other Metzner Maschinenbau GmbH products

Rubber and Plastics Processing - Profile Processing

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- Knife cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Cutting machine for the automotive industry

- High-performance cutting system

- Compact cutting system

- Rotary blade cut-off machine

- Steel cutting system

- Marking cutting system

- Profile cutting center

- Economical cutting system

- Textile cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.