- Production Machines

- Cutting Machine

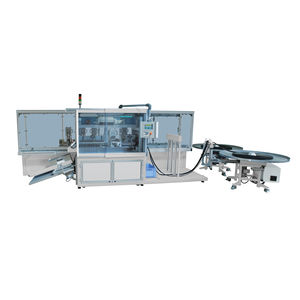

- Guillotine cutting machine

- Metzner Maschinenbau GmbH

Guillotine cutting machine ST 25for plasticsfor rubberprofile

Add to favorites

Compare this product

Characteristics

- Technology

- guillotine

- Material

- for plastics, for rubber

- Product handled

- profile

- Control type

- PLC-controlled

- Other characteristics

- eccentric

Description

If a die cut at very high speed is required and the pneumatic drive has reached its limit, the eccentric-drive cut opens new possibilities in terms of cutting performance.

With the Metzner ST 25, instead of a pneumatically driven cutting tool, we use an electrically-driven eccentric mechanism bearing the cutting tool. In this way, we can achieve ground-breaking guillotine cutting performance of up to 800 cuts/minute. A beneficial side effect: the electric drive enables the ST 25 to work very quietly, making this model the choice for customers in low-noise environments.

Metzner offers for eccentric drive cutting machines two cutting modes: With the intermittent Stop-and-Go cut, the belt feeder transports the material to the exact position and stops briefly while the knife cuts through the material. Due to the brief stop, high length accuracy and a precise right-angled cut are achieved. The feeder does not stop for the continuous cutting method. The material is continuously transported and cut simultaneously. In this way, the production output can be increased. The cutting quality here is still good, but not as perfect as the intermittent Stop-and-Go cut.

Key Features

• Eccentric drive cutting machine up to 800 cuts per minute

• Outstanding cutting quality and length accuracy

• Choice of »Stop & Go« cut or continuous cut

• Maintenance-free servo motors for cutting and feed units

• High blade service lives

• Silent operation

• Large program memory for all machining parameters

VIDEO

Catalogs

Other Metzner Maschinenbau GmbH products

Rubber and Plastics Processing - Profile Processing

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- Knife cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Cutting machine for the automotive industry

- High-performance cutting system

- Compact cutting system

- Rotary blade cut-off machine

- Steel cutting system

- Marking cutting system

- Profile cutting center

- Economical cutting system

- Textile cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.