Design software developmentcontroltest

Add to favorites

Compare this product

Characteristics

- Function

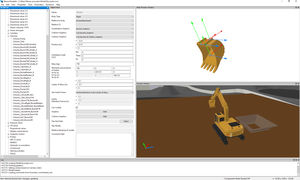

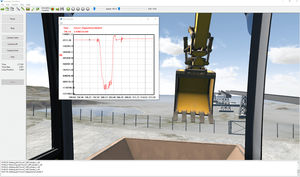

- design, development, control, test, virtual prototyping, multibody simulation

- Applications

- process

- Type

- real-time

Description

Design and manufacture even the most complex and intelligent machines with ease

Mevea’s end-to-end digital twin solutions provide benefits in the product development by enabling transparent communication both internally and externally

With a single digital twin evolving from concept to testing and production, you can ensure that everyone on your team is on the same page

BREAK DOWN SILOS

Everyone is working on the same model in real time, allowing better cooperation

Product information flows through the digital thread across departments

Right information in the right place at the right time

Cross-functional teams can help your company develop

VIRTUAL PROTOTYPING

No need for numerous physical prototypes; iterate virtually until ready for production

Achieve significantly shorter lead times and decrease the cost of prototyping

Real-time multibody simulation includes the machine, environment, work process as well as control systems

Test the individual components of the product and how it all works together in the environment and the task it was designed to operate on

COMMUNICATE WITH ALL STAKEHOLDERS

Recognise downstream issues earlier and avoid late, and costly, design changes

Involve the customer more closely in the development process, and receive happier end-users in return

Visual demonstration of the product under development increases transparency among the stakeholders

Catalogs

No catalogs are available for this product.

See all of MeVEA‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.