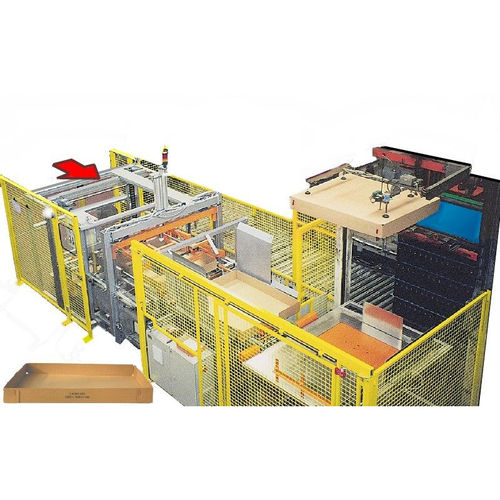

B04 Fully Automatic Stapling Machine

SHA 81/LIFT. Stapling cardboard flats to trays

Feeding > Shaping > Stapling >Reversing >Ejecting > Handing-over

Application range

For shaping and stapling flat carton blanks of solid or corrugated cardboard to trays

(bottoms or lids).

For integrated application.

A pallet of carton blanks of solid or corrugated cardboard is positioned in the lifting station by means of a fork-lift-truck and are lifted from there.

Automatic functions:

> Lifting and feeding the blanks.

> Shaping to carton tray.

> Single or double stapling the 4 flaps.

> Ejecting trays into transfer device for handing-over or lifting.

Additional functions optionally:

> Turning tray bottoms to tray lids.

> Pushing over and centring in a transfer station.

Output: 3 – 4 trays / minute.

Technical Description

• 4 Stapling heads > B 36 - 60 (B 36 -70) for coiled staples.

• Loading capacity of 1 stapling head: 4000 coiled staples.

• Coiled staples MG® B 60.

• Reloading time for 1 coil: less than 1 minute.

• Single or double stapling from 120 mm rim height.

• Adjustable for different tray sizes made of solid, single or double corrugated cardboard.

• Adjustment to other tray size: 2 - 3 minutes.

• Main frame with safety doors.

• Equipped with 4 castor wheels for easy moving.

• Equipped with 20 l pressure tank to compensate pressure oscillations.

• Pick up height: 1150 mm;

• Ejecting side: 1100 mm.

• Effective height: 1100 mm.