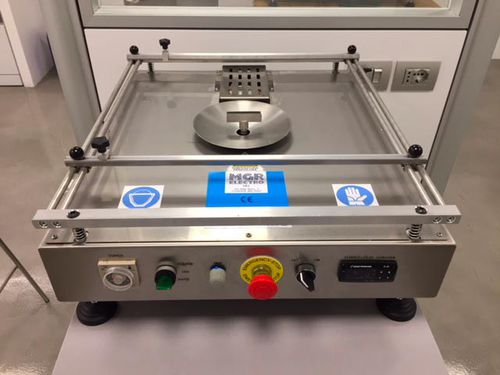

NEW MINIWAVE is a solder station for lead-free alloys and not, built by MGR ELECTRO to find use in electronic and electromechanical companies where there is the need to carry out operations of tinning – soldering – unsoldering welding components in tin alloys.

It can be used both inserted in automatic machines to perform tinning operations on wires, coils or other components and in bench version by applying fixed or interchangeable nozzles with dedicated forms (see photos below).

In both solutions MGR ELECTRO can provide a kit of fluxing to be implemented in the same stations.

NEW MINIWAVE may be employed where you need to have a moving tin wave, and so clean, that allows to perform tinning/welding operations of components or rework of the same on electronic circuit boards where it’s required the use of a tin mini-wave at room temperature and controlled levels.

All parts in contact with tin alloy are made of titanium and therefore free from corrosion by lead-free alloys. The disassembly and then its maintenance are very simple and fast.

– LENGHT: 330 mm

– WIDTH: 120 mm

– HEIGHT: 370 mm

– EMPTY WEIGHT: 7 Kg

– LADEN WEIGHT: 16 Kg

– ALLOY CAPACITY: 9 Kg

– MAXIMUM SIZE OF NOZZLES: 12 cm

– POWER CONSUMPTION: 830 W

– POWER SUPPLY: 230 V