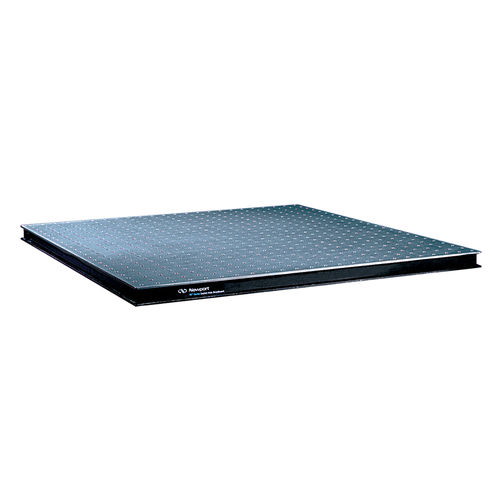

Composite core optical breadboards are designed for applications that do not require much damping. They are the most cost effective, light weight solution for less demanding applications.

•Low cost 28 mm thick breadboards for less demanding applications

•Light weight composite core

•3.4 mm 400 Series Stainless Steel working surface

•19 mm deep sealed holes with easy clean polymer cup

Individually Sealed Mounting Holes

All of Newport's optical breadboards are designed with individually sealed mounting holes. Those mounting holes feature 19 mm screw depth. In contrast to some of the other products in the market that has channel for a row of holes or just a polymeric film, Newport's individually sealed holes are more reliable and easier to clean. This is because we believe in the integrity of the product - especially the core. When dust and liquids go into your optical breadboard and table, it may have a long term effect on the damping performance of the product and make the product degrade over time. A good quality breadboard and table lasts long time - tens of years and more. It's a good investment for a product with sealed mounting holes.

Highly Damped Side Panel

Side panels for optical tables do more than just covers. They should contribute to the overall damping performance of the table. Newport's optical breadboards and tables use highly damped composite wood as side panels to help eliminating vibrations from the side. Composite wood has much better damping performance than steel – it simply does. Materials with a high elasticity (steel, for example, and other hard metals) tend to allow vibration or ringing.