- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

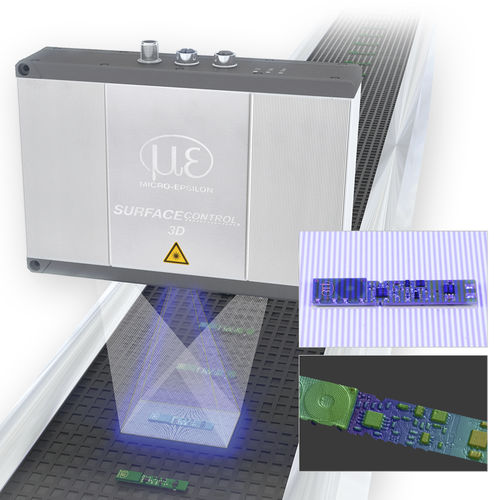

3D vision sensor surfaceCONTROL 3D 3500for object detectionfor pattern detectionfor optical detection

Add to favorites

Compare this product

Characteristics

- Type

- 3D

- Applications

- for object detection, for pattern detection, for optical detection, for defect detection, for presence detection, robotic

- Other characteristics

- compact, stand-alone, all-around

- Resolution

Min.: 1 µm

Max.: 2 µm

Description

The surfaceCONTROL 3500 3D sensor is used for inline inspection of geometry, shape and surface on diffusely reflecting surfaces such as metal, plastic or ceramics.

The high-precision surfaceCONTROL 3D 3500 is a 3D snapshot sensor which is ideally suited to automated inline inspection of geometry, shapes and surfaces on diffuse reflecting surfaces. The sensor works according to the principle of fringe projection, which allows direct 3D measurement of components. The surfaceCONTROL 3D 3500 stands out due to its compact design and high measurement accuracy combined with high data processing speed. Two models cover different measuring fields. With a z-repeatability up to 0.4 µm, the sensor sets a new benchmark in the high precision 3D measurement technology. This is how even the slightest of planarity deviations and height differences can be reliably detected.

In addition to the fast data output via Gigabit Ethernet, the sensor offers an additional digital I/O interface. The 2D/3D gateway offers EtherNet/IP, PROFINET and EtherCAT connections. Powerful software tools enable precise 3D measurements and surface inspection. GigE Vision compatibility also allows easy integration into third-party image processing software. The

comprehensive SDK for customer software integration rounds off the software package.

Catalogs

No catalogs are available for this product.

See all of MICRO-EPSILON‘s catalogsOther MICRO-EPSILON products

3D Sensors for geometry and surface inspections

Related Searches

- Digital camera module

- CMOS camera module

- Industrial camera system

- Infrared imager

- Surveillance camera

- USB camera module

- Waterproof camera system

- Compact imager

- Thermal camera

- High-definition camera

- Inspection system

- Temperature-controlled camera

- Spark optical emission camera system

- Industrial endoscope

- Inspection machine

- IP67 imager

- Lightweight camera module

- Flexible industrial endoscope

- Medical camera module

- Video endoscope

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.