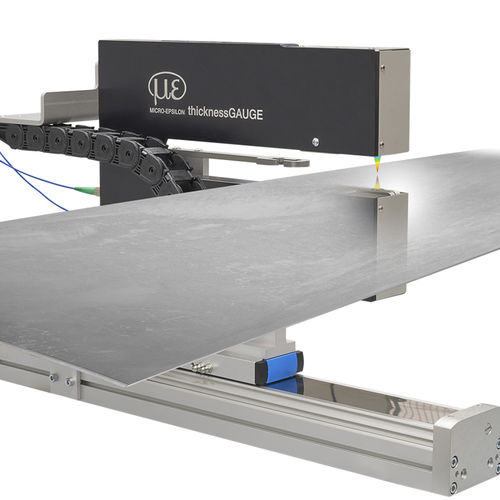

Stationary thickness gauge thicknessGAUGE C.Cglassfor thin materialsdry film

Add to favorites

Compare this product

Characteristics

- Type

- stationary

- Applications

- glass, for thin materials, dry film, film, foil, for sheet materials

- Technology

- non-contact, confocal chromatic, spectral reflectance

- Calibration

- automatic calibration

- Other characteristics

- high-resolution, in-line, contactless, with integrated probe

- Measuring range

2 mm

(0.08 in)- Measurement accuracy

4 µm

- Measurement width

Max.: 400 mm

(15.7 in)Min.: 200 mm

(7.9 in)- Resolution

40 nm

- Ambient temperature

Max.: 45 °C

(113 °F)Min.: 5 °C

(41 °F)

Description

The thicknessGAUGE C.C sensor systems use confocal chromatic displacement sensors for the thickness measurement. The sensors allow for measurements to be performed with outstanding accuracy and high measuring rates. In addition, this innovative measuring technique enables measurements of reflective and shiny surfaces as well as (semi-)transparent measuring objects.

The thicknessGAUGE sensor systems are used in strip processes and plate production in

order to measure the thickness continuously at individual measuring points. These systems are designed in such a way that they can be used as both initial equipment and for retrofitting of existing facilities. Based on high precision and equipped with intelligent sensor technology, these sensor systems are used in various industries.

Powerful analysis and control software:

thicknessGAUGE systems are equipped with a multi-touch capable software package for

analysis, presentation and archiving of monitored production data. This software enables

different measurement modes such as fixed track thickness measurement at any position,

measurement of the thickness profile, measurement of several longitudinal trends, an SPC

package and automated verification of the measuring system's capability. It ensures easy

and fast verification of the measuring system capability which is individually adjustable.

Features for documentation and process control:

Article database

Production archive

Statistical evaluations

Limit value monitoring with return back to production (optional fieldbus interfaces)

Verification of measuring system capability

VIDEO

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Measuring device

- Digital measuring device

- MICRO EPSILON thickness gauge

- Micrometer

- Measurement scanning system

- 3D scanning system

- Laser scanner

- Inspection scanning system

- Digital micrometer

- 2D scanning system

- High-precision scanning system

- High-resolution scanning system

- Compact scanning system

- High-speed scanning system

- Analog measuring device

- Analog micrometer

- Metal thickness gauge

- MICRO EPSILON stationary thickness gauge

- Automatic calibration thickness gauge

- Optical scanning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.