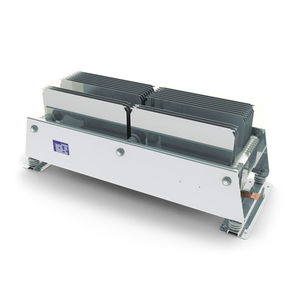

Braking resistor for railway applicationsair cooledstainless steel

Add to favorites

Compare this product

Characteristics

- Applications

- braking, for railway applications

- Other characteristics

- air cooled, stainless steel

Description

Braking Resistors are used to transform kinetic energy of the vehicle into heat by means of electric braking.

Braking Resistors are usually installed:

On the roof of a vehicle, where hot exhaust air is released upward

Under frame, where the hot air released is exhausted sideways when the vehicle is in motion or using a blower

Inside the vehicle, where the resistors are usually forced air cooled, where fresh air is taken from the bottom of the vehicle and hot air is expelled from the top

Resistor elements are assembled in banks by means of strong rods and ceramic spacers. Segments of resistor banks are mounted in a strong support frame of AISI304 stainless steel.

Stainless steel is also used for bolts, nuts and washers. The resistors are designed to avoid disturbing noises caused by pulsating current.

Resistors are designed by our engineers with a sophisticated 3D model in order to find the best solution for our Customers and to withstand shocks and vibrations that normally occur in operation. Design and production, strictly follows our ISO 9001:2008 and IRIS Rev. 2 quality standards as well as the most severe international specifications.

All our resistors are type tested at our test lab where real service conditions can be reproduced via mock-up and motion air flow simulation. All Microelettrica Scientifica locations are equipped with dedicated testing facilities to guarantee product compliance with specification requirements.

A Railway Resistor is a 100% custom made product, where a few constructive and technological principles are applied in a project-specific mechanical frame layout.

Catalogs

No catalogs are available for this product.

See all of Microelettrica‘s catalogsRelated Searches

- Power resistor

- Electronic fan

- Axial electronic fan

- Voltage resistor

- Braking resistor

- Current resistor

- Compact resistor

- Low-inductance resistor

- Flat resistor

- Over-voltage resistor

- Damping resistor

- Pulse resistor

- Grounding resistor

- Discharge resistor

- Neutral resistor

- Standard resistor

- Test resistor

- Insulated resistor

- Stainless steel resistor

- Filter resistor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.