- Metrology - Laboratory

- Laboratory Equipment

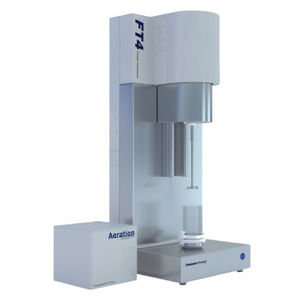

- Automatic sample preparation system

- Micromeritics Instrument Corp.

- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic sample preparation system VacPrepfor the laboratory

Add to favorites

Compare this product

Characteristics

- Operation

- automatic

- Applications

- for the laboratory

Description

The VacPrep features six degassing stations, and a choice of vacuum or gas flow preparation on each of the six stations.

The VacPrep™ 061 offers two methods for removing contaminants. In addition to flowing gas, it provides vacuum to prepare samples by heating and evacuation. This combination allows you to choose the preparation method that is best suited to your material or application. The VacPrep features six degassing stations, and a choice of vacuum or gas flow preparation on each of the six stations. Needle valves are also provided allowing you to introduce the flowing gas or vacuum slowly to prevent fluidization of samples.

Specifications

Sample Tubes: Up to 3.0-cm (1 3/16-in.) OD bulbs with 1/4-, 3/8-, or 1/2-in., 9mm, 12mm OD stems.

Heating Block:

Temperature: 10 ºC above ambient to 400 ºC

Temperature Accuracy: ±10 ºC

Electrical

Voltage: 100, 120, 220, 240 VAC r10%

Power: 250 VA maximum

Frequency: 50/60 Hz

Environment

Temperature: 10 to 35 ºC operating; 0 to 50 ºC non-operating

Humidity: Up to 90% relative, non-condensing

Gases Used: Helium, nitrogen, argon, or any other pure gas that does not adsorb at room temperature.

Flow Rate (flowing gas preparation): Up to 50 cm3/min.

Vacuum System

A vacuum source achieving better than 20 µmHg at the instrument inlet, and having a device to reduce oil vapor

backstreaming is recommended.

The vacuum system must also have an anti-suckback valve to prevent oil from flowing into the VacPrep should there be a power failure.

Sample Capacity: Six ports, each with a heating and a cooling station

Physical

Height: 43 cm (16.95 in.)

Width: 36 cm (14.3 in.)

Depth: 30 cm (11.87 in.)

Weight: 10 kg (22 lbs)

Catalogs

Other Micromeritics Instrument Corp. products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.