- Products

- Catalogs

- News & Trends

- Exhibitions

Hard anodizing OX-H seriessulfuricaluminumautomotive

Add to favorites

Compare this product

Characteristics

- Type

- hard, sulfuric

- Type of substrate

- aluminum

- Applications

- automotive

- Certifications

- MIL-A-8625, Type III, ISO 10074

Description

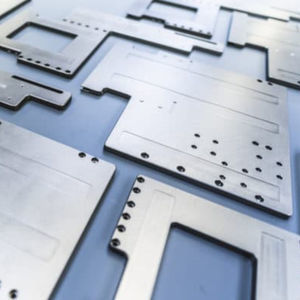

OX-HS is a hard anodizing treatment of aluminium in sulphuric acid in compliance with MIL-A-8625 Type III, ISO 10074, and UNI 7796 standards.

The OX-HS hard anodizing process transforms the aluminium alloy surface, creating an inert and compact layer of aluminium oxide. The electrochemical process takes place in a sulphuric acid solution at temperatures below 0°C, making it possible to reach very high treatment thicknesses.

The OX-HS treatment features surface hardness that protects the aluminium base from abrasive and adhesive wear. The coating is customarily used in the automotive sector and for industrial machinery to extend the lifetime of parts subject to wear and sliding motion.

The non-conductivity, compactness, and chemical resistance of the coating make it possible to protect the aluminium substrate from corrosion, exceeding 1000 hours of salt spray without the onset of corrosion. For this reason, the coating is used to protect submarine components and components in the maritime and military sectors

HIGH CORROSION RESISTANCE

The compact OX-HS film protects the substrate material from corrosion, exceeding 336 hours of salt spray exposure with no trace of corrosive attack.

HIGH WEAR RESISTANCE AND HARDNESS

The hardness and compactness of the layer of aluminium oxide allows the achievement of high abrasive and adhesive wear resistance, comparable to that of hard chrome.

Related Searches

- Anodic oxidation

- Aluminum anodic oxidation

- Anodic oxidation with coloring

- Nickel plating

- Electroless nickel plating

- ISO 9001 anodic oxidation

- ISO 9001 nickel plating

- Hard anodizing

- Automotive anodic oxidation

- Medical anodizing

- Industrial anodizing

- High phosphorus nickel plating

- Titanium anodizing

- Steel nickel plating

- Aluminum nickel plating

- Stainless steel nickel plating

- Copper nickel plating

- Sulfuric anodic oxidation

- Brass nickel plating

- Bronze nickel plating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.