The pico+TF sensors are ideal for the non-contact fill level measurement of chemically aggressive liquids or granules.

Highlights

PTFE membrane for protection against aggressive media

M22 sleeve in PVDF

IO-Link interface for support of new industry standard

Automatic synchronisation and multiplex operation for simultaneous operation of up to ten sensors in close quarters

Basics

1 Push-Pull switching output pnp or npn basis

microsonic Teach-in on pin 5

0.069 mm resolution

Temperature compensation

10–30 V operating voltage

LinkControl for configuration of sensors from a PC

Description

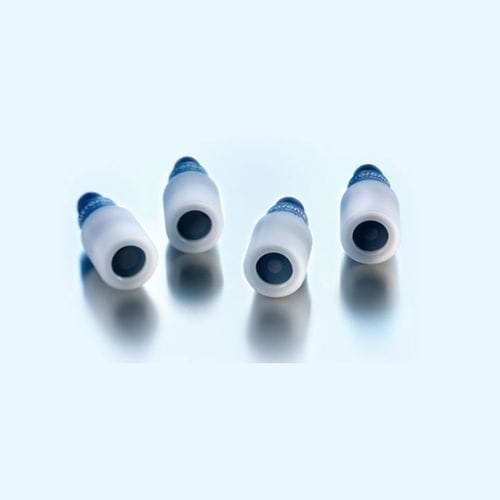

pico+TF ultrasonic sensors

The compact dimensions of the pico+TF sensors makes them ideal for fill-level measurement in housings of restricted dimensions. The ultrasonic transformer is protected against aggressive media by a PTFE film. The exterior PVDF coating with its M22 x 1.5 external thread seals the ultrasonic transformer from the sensor housing.

The M22 sensors detect in a contactless fashion and are reliable within a measuring range of 20 mm to 1,300 mm. The ultrasonic sensor is the best choice for non-contact fill level measurement with chemically aggressive liquids or granules.

A typical application for these sensor line is the fill level monitoring of aggressive paints and inks such as those used in the digital printing sector. These inks often contain ketone. In addition to the high chemical resistance of the sensor, its size makes it especially suited to use in restricted spaces. Regular filling and emptying of the tank can produce wave motions in the tank system, which can be compensated using the internal filter setting.