Automatic probe station LCS- 4000semi-automaticwith laser cutting function

Add to favorites

Compare this product

Characteristics

- Type

- automatic, semi-automatic, with laser cutting function

Description

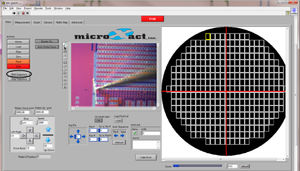

The LCS-4000 Probe Station with Integrated Laser Cutting System gives the user maximum flexibility in semiconductor diagnostic cutting, failure analysis, trimming, marking and topside layer removal. All of these functions can be performed on a microscopic level, all on this one system, which provides a high level of performance that is remarkably easy to use.

The integrated laser cutting system can be used to alter conductors on integrated circuits by laser ablating contact leads, sacrificial layers and other materials without damage to the devise internals. This laser trimming process allows for selective layer removal, such as topside layer removal, and can aid in semiconductor failure analysis or for fine tuning device characteristics, such as resistance, capacitance or RF properties. MicroXact’s laser cutting system is also capable of isolating faulty components by cutting the metal lines that connect the faulty component to the rest of the circuit. Pre-built logic includes automated identification of faulty devices on the wafer and erasing these devices from the wafer completely via ablation.

The LCS-4000 is offered as a motorized, semi-automated or fully-automated configuration system and can easily be configured for a wide range of applications with a variety of design options and accessories available.

LCS-4000 Probe Station Features

• System integrates the Laser Cutting System for selectively removing material, such as topside layer removal, making high-precision cuts and marking metal.

• Designed for simultaneous DC and/or RF probing while laser trimming leads or removing defects from devices.

Catalogs

LCS-4000

4 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.