Optimal chip removal, extraordinary tool life, high productivity and simultaneously excellent surface quality – all of these requirements are met by CrazyDrill Alu from Mikron Tool. The tungsten carbide drill for aluminum guarantees that its user enjoys maximum profitability. Due to its three-flute geometry it is self-centering.

This CrazyDrill drill for cast and wrought aluminum alloys produces extraordinary machining results. Most notably it impresses with its extraordinarily high drilling speed and tool life. This type of drill bit is not only impressive in pure aluminum because of the especially adapted coating, it also exhibits a considerably longer tool life compared to other available tools in the market when machining silicon-based aluminum alloys.

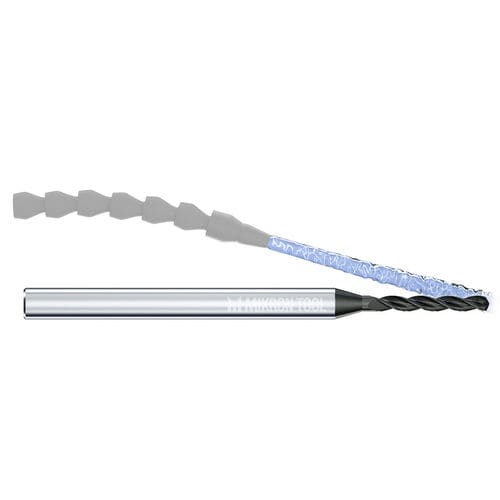

This drill for aluminum is self-centering due to its three flutes. This means centering or pilot drilling, which is needed in long twist drill types, is no longer required.

A straight hole (no deviation), the best roundness and high hole surface quality are ensured. Pilot drilling or centering is only recommended on an irregular or inclined material surface and, if needed, for higher position accuracy. These are carried out ideally with CrazyDrill Pilot or with CrazyDrill Crosspilot when drilling on inclined, convex or concave surfaces. Both pilot drills are perfectly adapted to CrazyDrill Alu in terms of diameter and tolerance (no measurable transition and no jamming).

Its helical groove geometry provides for optimal chip flow and only minimum chip removal is needed (for drilling depths > 5 x d). With its external cooling CrazyDrill Alu is the optimal