- Machine-tools

- Cutting Tool

- Solid drill bit

- Mikron Group

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

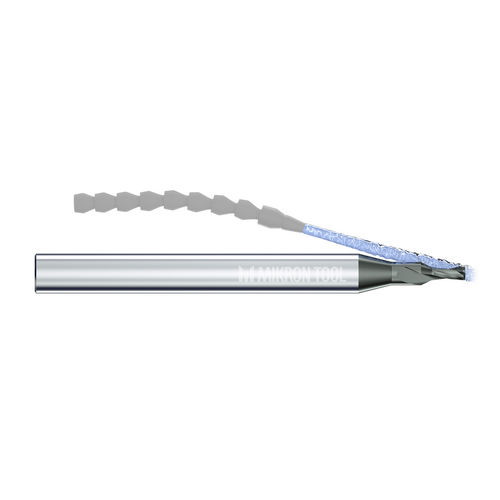

Solid drill bit CrazyDrill Crosspilotfor titaniumfor non-ferrous metalsfor steel

Add to favorites

Compare this product

Characteristics

- Type

- solid

- Drilled material

- for titanium, for non-ferrous metals, for steel

- Drill bit material

- tungsten carbide

- Other characteristics

- coated, high-performance, twist, milling

- Diameter

Max.: 6.35 mm

(0.25 in)Min.: 0.4 mm

(0.02 in)- Length

50 mm, 55 mm, 65 mm, 70 mm, 80 mm

(1.97 in, 2.17 in, 2.56 in, 2.76 in, 3.15 in)

Description

The coated tungsten carbide drill for steel, stainless steel materials, titanium and nonferrous metals (CrazyDrill Crosspilot from Mikron Tool) is a unique specialist for holes on inclined, convex and concave surfaces. It produces pilot holes directly in surfaces with up to a maximum inclined angle of 60°, which does not correspond to a DIN centering hole since no circular chamfer can be made on an inclined surface.

This means the solid carbide drill bit reduces the three steps needed up to now ( milling – centering – drilling) to two steps and simultaneously guarantees a higher degree of precision due to good guidance. Its compact and sturdy design provides for good position accuracy. Its geometry is designed for extreme applications. The 170° tip angle of the CrazyDrill Crosspilot affords the follow-up drill stability, thus preventing cutting edge breakage. The pilot drill can be supplied from stock in diameters of 0.4 mm to 6.35 mm (.016” to .250”, fractional inches available), suitable for the existing CrazyDrill program.

Provided a tool meets a work-piece at right angles, centering or direct finish-drilling poses no problem. However, if the holes go diagonally through the part or if the surfaces are inclined, drilling becomes difficult. The forces exerted complicate the accurate drilling process considerably.

The design of the pilot drill CrazyDrill Crosspilot allows to drill a hole at an angle with up to a maximum inclination of around 60° to the surface. Due to its extreme drilling on inclined surfaces, it replaces the otherwise necessary milling operation and could therefore be called a milling drill bit for metal as well.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Mikron Group‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Mikron milling cutter

- Mikron solid milling cutter

- Mikron drill bit

- Mikron steel milling cutter

- Clamping milling cutter

- Mikron solid drill bit

- Mikron metal milling cutter

- Milling tool with cylindrical shank

- Mikron end mill

- Coated milling cutter

- Cast iron milling tool

- Mikron multi-purpose drill bit

- Mikron cutting milling cutter

- Hemispherical milling cutter

- Solid carbide milling tool

- Mikron carbide drill bit

- Roughing milling tool

- Corner radius milling tool

- Mikron high-performance milling cutter

- Mikron stainless steel milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.