- Materials - Tools - Components

- Semi-finished products

- Coolant

- Miller-Stephenson Chemical Co

Coolant MS-242N

Add to favorites

Compare this product

Description

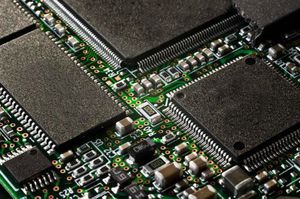

MS-242N Quik-Freeze® spray provides a rapid method of cooling small electronic components and epoxy/composite mixtures. Our freeze agent is typically utilized to locate intermittent malfunctions in electronic equipment and assist with release of stubborn, tacky epoxy/composites. Utilizing MS-242N Quik-Freeze® will have no permanent effect on the chemical structure of your material and is safe for all plastics, rubbers, composites, and epoxies. MS-242N freezes small areas to -55°F/-48°.

Miller-Stephenson offers MS-242N Quik-Freeze spray to provide a rapid method of cooling small electronic components and epoxy/ composite mixture. This product is utilized to locate intermittent malfunctions in electrical equipment. MS-242N Quik-Freeze® will have no effect on components operating properly but faulty components will be shocked into failure mode and immediately identified. MS-242N freezes small areas to -55°F/-48°C and is compatible most plastics, elastomers and metals. Additional product benefits Include:

Rapid Cooling for PCB’s and Composites

100% Nonflammable, Residue-free Cooling

Odorless, VOC Exempt, Low toxicity

NSN 6850-01-333-1841

RoHS2 and RoHS complaint

Miller-Stephenson MS-242N Quik-Freeze spray is particularly effective for composite manufacturers looking for a residue free, rapid cooling method for sensitive composite applications. MS-242 freeze spray offers superior cooling for targeted areas and has been to shown to help with particularly tacky epoxies and composites to held with releasing from surfaces it is stuck to.

Nondestructive testing of electronic and electromechanical systems

Heat-cold intermittence testing of electronic components

Catalogs

No catalogs are available for this product.

See all of Miller-Stephenson Chemical Co‘s catalogsOther Miller-Stephenson Chemical Co products

Specialty Products

Related Searches

- Protective covering

- Metal aerosol spray

- Hard cleaning job detergent

- Cleaning cleaning product

- Coating for industrial applications

- Plastic spray

- Epoxy resin

- Wire coating

- Coating for automotive applications

- Polymer coating

- Flammable spray

- Metal cleaning product

- Abrasion-resistant coating

- Duster spray

- Chemical coating

- Rubber coating

- Stripper

- Ceramic coating

- Composite resin

- Epoxy coating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.