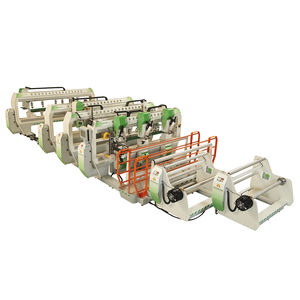

Fabric sewing and welding machine I4500fixedultrasonic

Add to favorites

Compare this product

Characteristics

- Applications

- fabric

- Configuration

- fixed

- Options and accessories

- ultrasonic

Description

Indexing Narrow and

WIDE REINFORCEMENTS

The I4500 is designed to weld all narrow webbings as well as wide reinforcement strips. This recipe driven curtain producer will enable your operator to easily finish your vertical webbing and vertical seams effortlessly. After the fabric is placed on the automatically driven table, the welding head will advance to the start position and finish all of the vertical webbings hands free. All webbings are pre-fed, pre-cut and precisely positioned with no measuring.

Hot Air Welding Applications:

• Woven Polypropylene

• Woven Polyethylene

• PVC Laminate

• PVC Coated

• Polyurethane Coated

• Polypropylene

+ More

Technical Specification

Voltage:

80 Amperes

Single/Three Phase - 208-240 Volts

80 Amperes

Three Phases, Plus Neutral 380-415 Volts

Air Requirements:

100 PSI @ 5 CFM

Power Consumption:

Approx. 19.2Kw or 22Kw

Maximum Temperature:

750° C (1382°F)

Throat Width:

4.5m (14.76ft)

Seam Width:

0.012m - 0.05m (.5in – 2in)

Welding Cycle:

Approx. 10m/min (32ft/min)*

Features and Benefits

1. Carriage with 2 independent heat systems for multiple welding widths.

2. Custom weld roller support to reduce material handling.

3. Automated rotary webbing cutter reducing operator labor.

4. PLC Smart Screen with recipe storage for guide setting recall.

5. High speed hot air welding technology for increased production.

VIDEO

Catalogs

I4500

2 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.