- Machine-tools

- Machine Tool Accessory

- Machine tool CNC controller

- Milltronics Manufacturing

Machine tool CNC controller 9000-DGIfor lathesfor turning centerstouch screen

Add to favorites

Compare this product

Characteristics

- Applications

- for machine tools, for lathes, for turning centers

- Other characteristics

- touch screen

Description

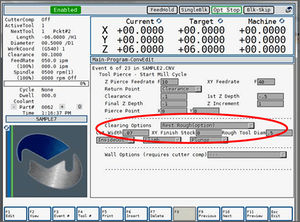

With its conversational programming, on screen help, intuitive menus, color graphics, and prompted tool settings, the 9000-DGI CNC helps new operators get up to speed quickly. The 9000-DGI CNC makes it the one machine in the shop that everyone wants to operate.

The 9000-DGI CNC is packed with features that allow quick and confident operation of the CNC:

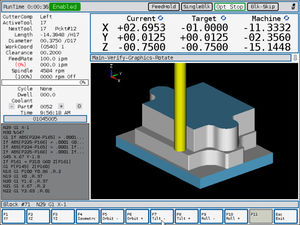

Solid model graphics allow the operator to see a completed part prior to cutting.

Mid program restart allows the operator to start anywhere in a program by verifying the graphics and then switching to Run Mode. It’s simple – no need for G&M code expertise!

Handwheel run allows the operator to run a program in a controlled mode where motion only

occurs while the handwheel is turning. This feature allows operators to verify programs with total control and complete confidence.

The 9000-DGI CNC features a dual-core processor and high-speed motion control that is capable of executing 3,000 blocks per second. Execute the most demanding programs in the shortest time.

The 9000-DGI CNC is equipped with a 120 GB solid state drive, 4 GB RAM memory, USB ports and

Ethernet connectivity.

The 9000-DGI CNC allows operators to run parts programmed conversationally or tool paths generated by a CAM system. Coupled with a superfast motion control system, feature-packed CNC, and an interface designed to expedite setup and operation, the 9000-DGI CNC is the solution to helping your operator make parts faster and better.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Milltronics Manufacturing‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.